Bathroom Waterproof Materials: The Science of Keeping Every Surface Dry and Damage-Free

Few places challenge materials like a bathroom does. Constant moisture, temperature shifts, and daily cleaning chemicals turn every joint, tile, and corner into a testing zone. Once water penetrates beneath the surface, it breeds mold, weakens adhesives, and corrodes structure.

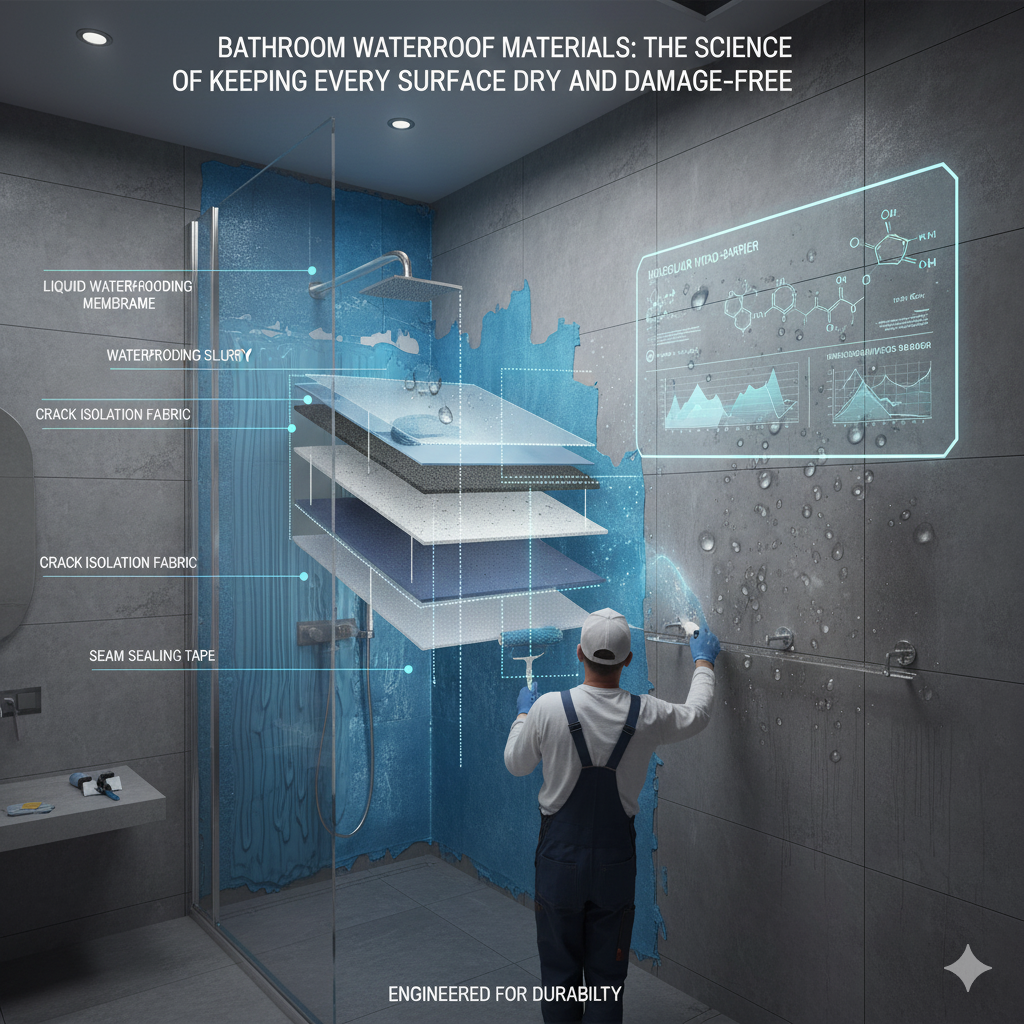

That’s why modern bathroom waterproof materials go far beyond simple coatings—they are engineered barrier systems combining polymers, minerals, and flexible binders to create a lasting seal beneath visible finishes.

1 | Why Bathrooms Leak: Hidden Stress Below the Surface

Even a perfect tile finish can hide early-stage water damage. Most leaks stem from:

-

Capillary seepage through porous cement layers

-

Thermal expansion between tiles and substrate

-

Cracked joints from rigid, non-elastic grout

-

Improper slope or drainage leading to standing water

-

Inconsistent waterproof layer thickness during application

Over time, these issues allow moisture to creep behind tiles—causing black stains, odor, and costly rework.

2 | Core Categories of Bathroom Waterproof Materials

| Type | Composition | Key Advantages | Typical Area of Use |

|---|---|---|---|

| Cementitious Slurry | Cement + polymer modifiers | Breathable, cost-effective | Floors, walls, behind tiles |

| Liquid Polymer Coating | Acrylic / PU resin | High elasticity, easy application | Walls, ceilings, wet zones |

| Sheet Membrane | PVC / HDPE film | Excellent crack bridging, uniform thickness | Floors, shower bases |

| Hybrid Systems | Slurry + membrane | Dual protection for heavy moisture areas | Bathtub edges, balconies |

Each serves a purpose; professional installers often combine two or more to balance adhesion, flexibility, and vapor permeability.

3 | How Waterproofing Science Works

Modern formulations use polymer chemistry to make cementitious coatings flexible rather than brittle.

Key reactions include:

-

Hydrophobic network formation, repelling water molecules.

-

Polymer film bridging, sealing micro-cracks.

-

Crystalline growth within pores, permanently blocking capillary paths.

According to EN 14891 and ASTM C580, high-performance bathroom waterproof coatings must achieve ≥1 MPa adhesion and ≤0.1 kg/m²·h water absorption.

Brands such as YUNYAN follow these standards, testing each batch under simulated humidity cycles to ensure long-term reliability.

4 | Comparing Cementitious vs Liquid Polymer Systems

| Property | Cementitious Slurry | Liquid Polymer Coating |

|---|---|---|

| Flexibility | Moderate | High |

| Crack Bridging | 1 mm | > 2 mm |

| Vapor Permeability | Breathable | Low |

| Chemical Resistance | Moderate | Excellent |

| Cost Efficiency | High | Moderate |

| Application Ease | Trowel / Brush | Roll / Spray |

| Maintenance | Minimal | Re-coat after 5–8 yrs |

Choosing between the two depends on the room’s exposure and structure movement.

5 | Real Applications: Designing Leak-Proof Bathrooms

Showers & Wet Walls

Apply a two-component polymer slurry under tiles to resist constant splash and steam.

Floors & Drain Areas

Use sheet membranes beneath cement screeds to handle foot traffic and heavy load.

Bathtub Edges & Corners

Seal with elastic polyurethane coating and anti-mold grout to prevent capillary leakage.

Ceilings & Upper Walls

Lightweight acrylic film prevents moisture condensation and staining.

Each zone faces a different mix of humidity and stress—hence, integrated material systems outperform single-layer solutions.

6 | Selecting the Right Bathroom Waterproof System

Selection Checklist:

-

Confirm surface type (concrete, gypsum, old tiles)

-

Evaluate expected moisture load and usage frequency

-

Choose flexibility class (S1/S2 per EN 14891)

-

Verify VOC and toxicity standards for indoor use

-

Request TDS showing adhesion and elongation data

Recommended System Pairings

| Area | System Type | Lifespan |

|---|---|---|

| Shower wall | Polymer slurry + tile adhesive | > 10 yrs |

| Bathroom floor | Sheet membrane + cementitious layer | 8–12 yrs |

| Bathtub junction | PU liquid coating + sealant | 10 yrs |

| Ceiling | Acrylic film coating | 6–8 yrs |

7 | From Factory to Floor: How Manufacturers Like YUNYAN Ensure Performance

-

Automated polymer mixing for consistent elasticity.

-

Moisture-controlled curing rooms to simulate real bathroom conditions.

-

Batch QC reports including adhesion and absorption tests.

-

Green compliance formulas reducing VOCs and odor.

This manufacturing discipline turns waterproof materials from short-term fixers into engineered building systems that prevent recurring leakage.

Sealing Moisture Before It Becomes Damage

A reliable bathroom doesn’t depend on surface beauty—it depends on the unseen layer that keeps moisture contained.

Choosing the right waterproof material means choosing longevity, hygiene, and peace of mind.

For technical data, product guidelines, or OEM partnership details, visit YUNYAN’s official site.

For project-specific recommendations or supply consultation, reach our team via the contact page—and build bathrooms that stay dry for decades.