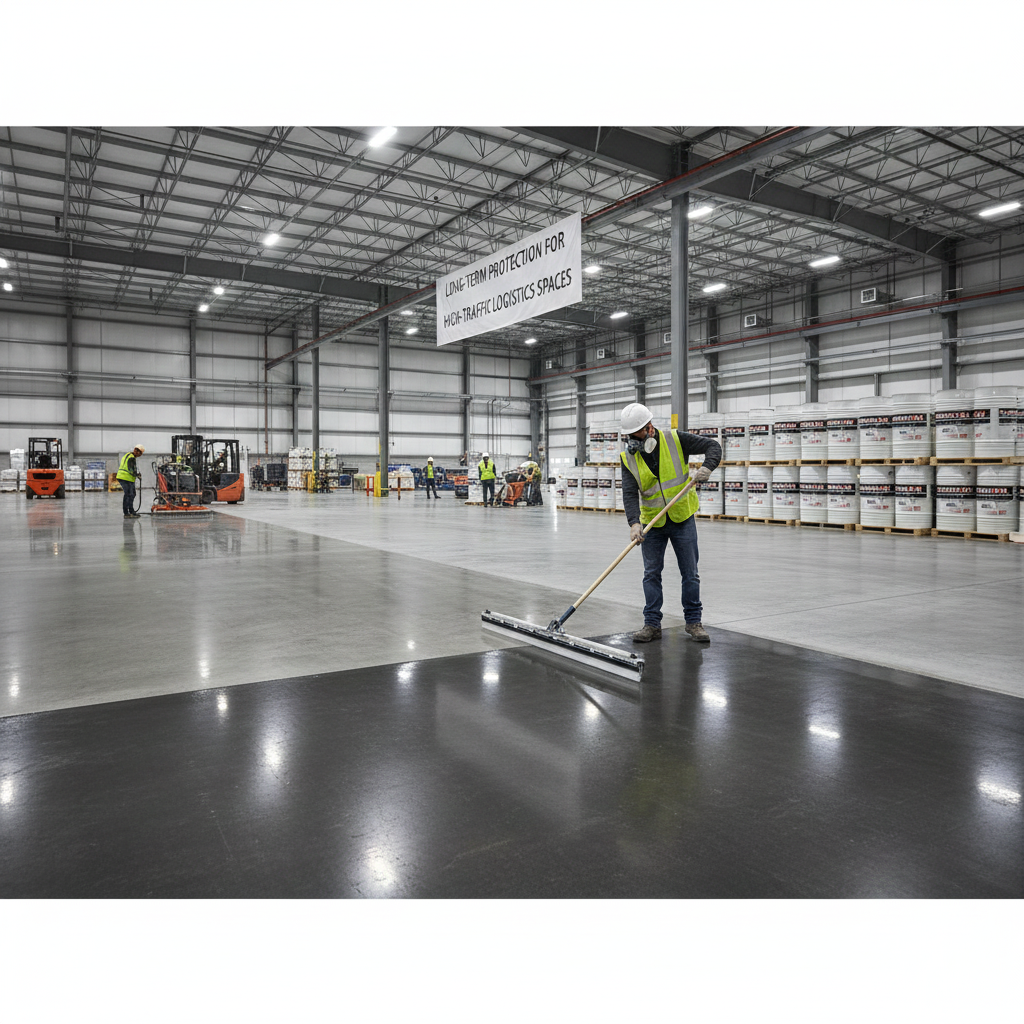

Epoxy-Based Floor Hardener Supplier: Precision-Bonded Strength for Industrial Durability

When forklifts roll, chemicals spill, and shifts run nonstop, the floor silently takes the hit.

Ordinary coatings crack under pressure, but epoxy-based floor hardeners transform raw concrete into a dense, impact-proof surface built to last for years.

Behind every resilient production floor lies a formulation of chemistry and precision—crafted by experts, refined for performance.

1 | The Core Challenge: Floors Under Constant Attack

Industrial floors operate in extreme conditions where traditional cementitious coatings fail.

Every day, the surface endures:

-

High mechanical load from machinery and vehicles.

-

Chemical erosion from oils, coolants, and solvents.

-

Thermal shock in foundries or food factories.

-

Moisture seepage that weakens concrete pores.

Once cracks appear, dust follows—and so do maintenance costs, safety hazards, and downtime. The answer lies in chemical bonding, not surface covering.

2 | How Epoxy-Based Hardeners Reinforce Concrete

Epoxy hardeners form a thermosetting polymer network that locks into the micro-structure of concrete.

Unlike surface paints, these hardeners chemically react to create a rigid, interlocking matrix that resists mechanical and chemical degradation.

| Component | Function | Result |

|---|---|---|

| Epoxy Resin (A) | Primary binder | Creates high-strength film |

| Polyamine Hardener (B) | Catalyst & cross-linker | Forms dense, non-porous network |

| Silica Filler | Load-bearing additive | Enhances compressive strength |

| Pigment & Anti-UV Agent | Color & stability | Prevents yellowing or fading |

Technical Parameters (YUNYAN Standard):

-

Compressive Strength: ≥ 85 MPa

-

Adhesion to Concrete: ≥ 1.2 MPa (ASTM D4541)

-

Abrasion Resistance: ≤ 0.6 g/cm² loss (ASTM D4060)

-

Chemical Resistance: Excellent (oil, alkali, mild acid)

-

Gloss Retention: > 5 years under continuous operation

These properties make YUNYAN’s epoxy floor hardeners ideal for heavy-duty environments demanding structural integrity and long service life.

3 | Comparison: Epoxy vs. Cementitious Hardeners

| Property | Cementitious Hardener | YUNYAN Epoxy-Based Hardener |

|---|---|---|

| Bond Strength | Mechanical only | Chemical + mechanical |

| Surface Density | Moderate | High, non-porous |

| Chemical Resistance | Weak | Strong |

| Finish Quality | Matte | Gloss / Semi-Gloss |

| Durability | 3 – 5 years | 8 – 10 years |

The chemical cross-linking of epoxy systems ensures that once cured, the floor becomes a solid monolith—immune to delamination or dusting.

4 | OEM and Supply Capabilities

YUNYAN operates as a global epoxy-based floor hardener supplier with strong OEM capability.

Every formulation is customizable to match regional climate, curing speed, or application equipment.

Manufacturing Highlights:

-

ISO 9001-certified automated blending and dispersion lines.

-

Batch-controlled resin viscosity and color calibration.

-

Private-label packaging in 5 L – 200 L export drums.

-

Custom curing times: fast-set (4 h) or standard (12 h).

-

Full compliance with ASTM D4060, EN 1504-2, LEED VOC limits.

OEM partners gain access to YUNYAN’s technical support and export documentation, enabling consistent product quality under their own branding.

5 | Where Epoxy-Based Hardeners Make the Difference

| Facility Type | Problem | YUNYAN Solution |

|---|---|---|

| Factories & Workshops | Abrasion, oil leaks | Epoxy hardener with anti-slip finish |

| Warehouses & Logistics | Forklift traffic | High-thickness self-leveling system |

| Food & Beverage Plants | Hygiene, moisture | Solvent-free epoxy formula |

| Aircraft Hangars | Chemical spills | Conductive epoxy protection layer |

| Parking Decks | Tire friction | UV-stable semi-gloss epoxy finish |

Each system is tailored for safety, appearance, and long-term ROI, ensuring facility floors remain functional and visually pristine.

6 | Application Process: Precision in Every Layer

| Step | Description | Key Control |

|---|---|---|

| 1. Preparation | Grind and vacuum clean surface | No dust or oil |

| 2. Priming | Apply low-viscosity primer | Deep pore penetration |

| 3. Main Coating | Mix A/B components 3:1 | Consistent blending |

| 4. Curing | 12 h standard or 4 h quick set | Temperature ≥ 15 °C |

| 5. Finishing | Optional topcoat polish | Gloss retention & easy cleaning |

Proper curing forms a dense, mirror-hard surface ready for decades of mechanical use.

7 | Why Clients Choose YUNYAN

-

Proven durability under 24/7 industrial load.

-

Consistent export quality with batch traceability.

-

OEM customization for private-label distributors.

-

Eco-friendly low-VOC formulations compliant with global standards.

-

Technical consultation for installation and maintenance.

YUNYAN’s commitment goes beyond materials—it’s about engineering trust and endurance into every floor.

Where Durability Meets Design

From manufacturing plants to logistics terminals, the right floor defines performance.

YUNYAN’s epoxy-based floor hardeners deliver unmatched hardness, shine, and protection, giving businesses the confidence to operate without interruption.

To learn more or request an OEM quotation, visit YUNYAN’s homepage or connect directly with our technical specialists through contact page.

Strong floors, strong operations—YUNYAN makes both possible.