YUNYAN company is a manufacturer, supplier, wholesaler and leading building chemicals' company in China, 2025 hot sale items are wear resistant self leveling epoxy floor coating, 3d epoxy resin for river table, self leveling epoxy cement for warehouse floor use, more informations please go through: http://www.yunyanchina.com

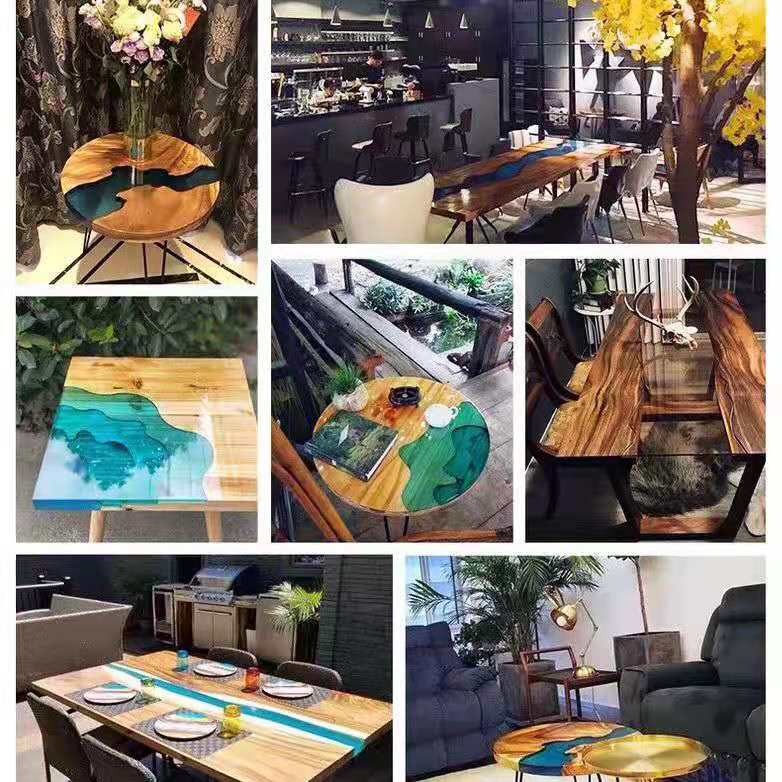

The popularity of custom furniture has soared, and at the forefront of this trend are stunning river tables. A key component to creating these masterpieces is the right epoxy resin for river tables. This material allows woodworkers to create a seamless, glass-like 'river' flowing between two live-edge wood slabs, resulting in a unique and captivating piece of art that doubles as functional furniture. Understanding the properties of this versatile material is the first step toward building a beautiful and durable piece that will last for generations.

Choosing the Right Epoxy Resin Type

Not all epoxies are created equal, and understanding the different epoxy resin types is crucial for a successful project. For river tables, you will primarily be looking for a 'casting' or 'deep pour' epoxy. Unlike coating epoxies, which are applied in thin layers, deep pour liquid epoxy resin is formulated with a lower viscosity and a slower curing time. This allows you to pour thicker sections, often two inches or more at a time, minimizing the need for multiple layers and reducing the risk of visible seam lines. This slow cure also helps air bubbles rise to the surface and dissipate, resulting in a crystal-clear, glass-like finish that is essential for the river effect.

The Pros and Cons of Epoxy in Woodworking

Before embarking on a project, it is wise to consider the epoxy resin pros and cons. On the plus side, epoxy is incredibly durable, resistant to scratches and moisture, and provides a stable, long-lasting finish. Its versatility is a major draw for anyone involved in epoxy resin for woodworking, as it can be poured into any shape and customized with colors. However, there are downsides. Epoxy can be expensive, especially for large projects. It also has a limited working time, or 'pot life,' once the resin and hardener are mixed. Furthermore, improper mixing or pouring conditions can lead to issues like bubbles, an uneven cure, or yellowing over time from UV exposure if the right inhibitors are not in the formula. Careful preparation and following instructions are paramount.

Food Safety and Customizing with Color

For tables intended for dining or food preparation, selecting a food safe epoxy resin is non-negotiable. Once fully cured, many high-quality epoxies are inert and considered safe for incidental food contact, but you must check the manufacturer's specifications to be certain. Beyond safety, one of the most exciting aspects of working with epoxy is the world of epoxy resin colors. You can achieve a vast range of looks, from a completely transparent, water-clear river to a vibrant, opaque flow. Pigment pastes, liquid dyes, and shimmering mica powders can be added to the mix to create pearlescent swirls, deep solid colors, or translucent tints, allowing for complete artistic control over the final appearance of your table.

More Than a Filler: The Adhesive Power of Epoxy

While we focus on its aesthetic role, the powerful epoxy resin adhesive properties are fundamental to a river table's structural integrity. The epoxy does not just fill the gap; it forms a tenacious bond with the wood grain on either side. This chemical bond secures the two wood slabs together, creating a single, solid unit that is incredibly strong and resistant to separation. This inherent adhesive strength ensures that your beautiful river table is not only a work of art but also a durable and functional piece of furniture that can withstand the rigors of daily use. This makes epoxy resin for woodworking an invaluable tool for both creative construction and repairs.

Final Considerations for Your Project

In conclusion, creating a stunning river table is an achievable and rewarding project when you understand the material. From selecting the correct deep pour liquid epoxy resin to considering the specific epoxy resin types and their properties, every step is important. By weighing the benefits and drawbacks, prioritizing safety with a food safe epoxy resin when needed, and exploring the creative potential of colors, you can harness the power of this versatile material. The right epoxy resin for river tables is not just a filler but the very heart of the design, providing strength, beauty, and endless creative possibilities for your woodworking endeavors.