PRODUCT DESCRIPTION:

YY-112 is a single component bagged polymer cement powder to be mixed with acrylic resin to install small size of tile or floor tiles with water absorption using the thin-set method of installation.

PRODUCT FEATURES:

Ø Interior and exterior use

Ø Add water only, user friendly

Ø Polymer cement based, add water only

Ø Green product, low VOC

Ø No asbestos

WHERE TO USE:

It is suitable for interior and exterior installation of granite, marble and all kinds of tiles’ bonding in small size with water absorption

Suitable Substrates:

Ø Concrete masonry

Ø Cement mortar beds

Ø Cement plaster

Ø =Brick masonry

Ø Cement terrazzo

PACKAGING:

Standard: 20kg or 25kg per bag

Ø 48 or 60 bags in a pallet

Ø Colors: gray/white

TECHNICAL DATA:

|

Status |

Single component |

|

Powder |

Gray or white |

|

Open time |

25min |

|

Pot life |

60min @25℃ |

|

Setting time |

≥4hours |

|

Construction |

Scrape |

|

Initial tensile adhesion strength |

0.7Mpa |

|

Initial tensile adhesion strength in water |

0.55Mpa |

|

Open time: Tensile adhesion strength after not less than 20min |

0.52Mpa |

|

Slip mm |

0.4 |

|

Shelf life |

12 months |

|

Condition on site |

5-40℃ |

UNIT COVERAGE:

1.2kg/mm/m2, one set 22kg can cover 5-6 square meters at 3mm thickness adhesive.

SHELF LIFE:

Sealed bags are guaranteed to be 12 months if stored at between 5℃ to 40℃.

HOW TO APPLY:

Surface Preparation:

All surfaces should be between 4°C and 32°C and structurally sound, clean and free

of all laitance, dirt, oil, grease, loose peeling paint, concrete sealers or curing compounds.

Dry, dusty concrete slabs or masonry should be dampened and excess water swept off. Installation

may be made on a damp surface. New concrete slabs shall be cured and 28 days old before application. Latex Portland cement mortars do not require a minimum cure time for cement slabs. All substrates must be plumb and true to 5 mm in 3 m when measured from the high point. Expansion joints shall be provided through the tile work, over all construction or expansion joints in the substrate. Do not cover expansion joints with adhesive.

Mixing:

Place 4.4L potable water into a clean pail and add 20KG 112 adhesive powde. Mix by hand or with a slow speed mixer to a smooth, even consistency.Allow adhesive to slake for 3 – 5 minutes. Remix without adding any more water or powder.

Application:

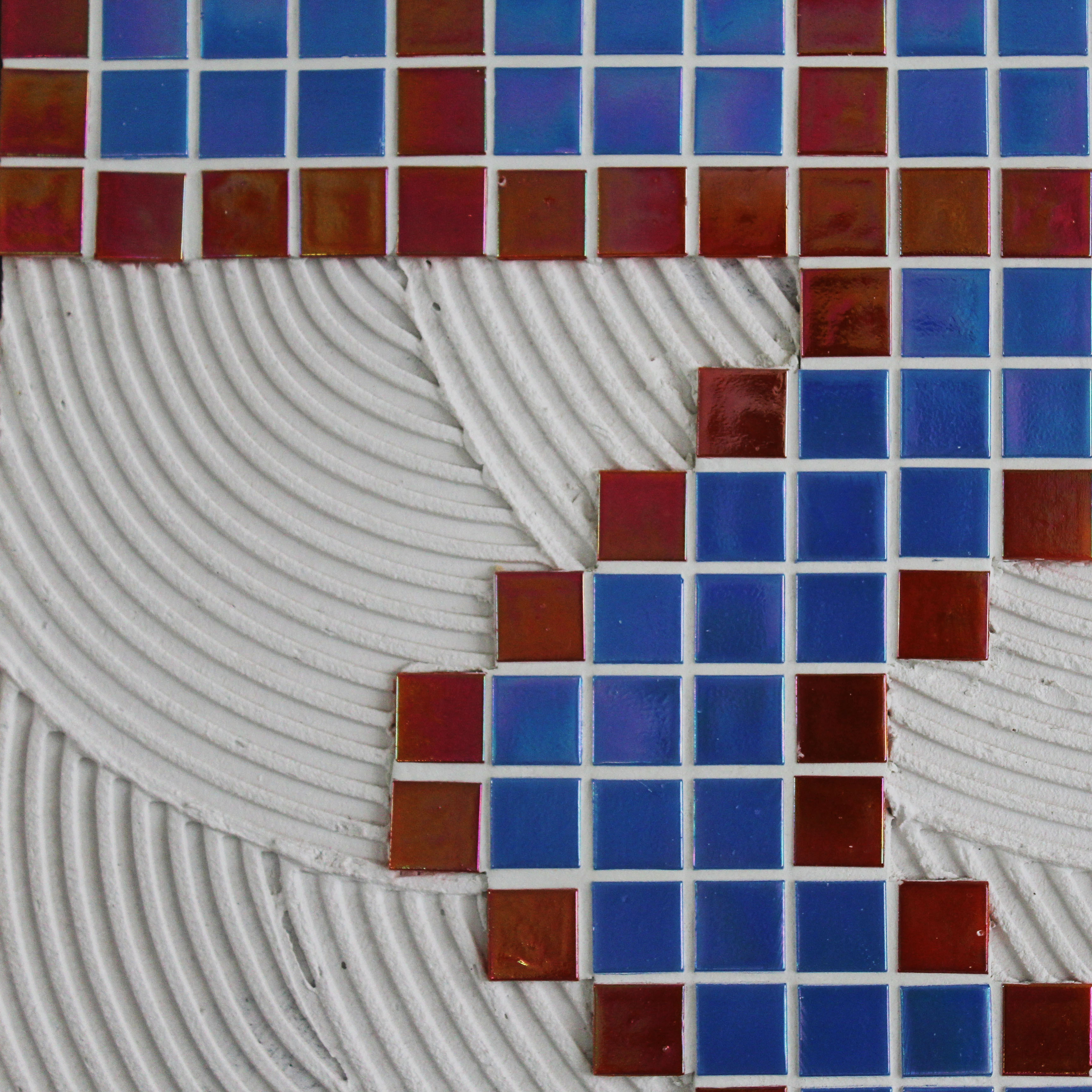

Apply adhesive to the substrate with the flat side of the trowel, pressing firmly to work into surface. Comb on additional adhesive with the notched side.

Joint Treatment

Grout after a minimum of 4 hours curing at 23°C or when dry

Exterior Application:

YY-315H2 water borne epoxy grout or YY-312 sanded cement based grout are recommended

Interior Application:

YY-315H1/315H2 epoxy grout or YY-315 smooth unsanded cement based grout are recommended.

Test area to ensure proper filling as narrow veneers and wide gaps behind the veneer may not allow for joint filling with an epoxy or cement grout.

Note: Control, expansion or other movement of joints must be treated with a flexible sealant.

Tile on Tile work

Existing ceramic tile must be firmly bonded to rigid floor construction. Tiled surfaces to receive tile must be prepared; shiny and highly glossed glazes should be removed by scarification; always cleaned to remove grease, wax, oil or any other contamination that will inhibit bond; clean with alkaline solutions like Tri-sodium Phosphate (TSP) or electric dishwasher powder and hot water after surface preparation (follow cleaning agent manufacturers safe use instructions) as required and rinsed with clean water and allowed to dry after cleaning.

Work a continuous skim coat into the surface, nominally 1.5 mm thick, of adhesive and vigorously work into the surface before combing additional adhesive over the skim coat using the appropriate sized trowel to suit the bedding requirements of the tile or panel

Cleaning

Clean tools and tile work with water while adhesive is fresh.

Cold Weather Note

The setting of Portland cement adhesives, mortars and grouts are retarded by low temperatures. Protect finished work for an extended period when installing in cold weather.

Hot Weather Note

The evaporation of moisture in Portland cement adhesives, mortars and grouts is accelerated by hot, dry conditions. Apply to dampened surfaces and protect freshly spread adhesive and finished work when installing in temperatures over 35°C.

YUNYANMIX C1 Tile adhesive is a kind of polymer mortar manufactured by YUNYAN company, YUNYANMIX is a well branded one of Top 10 for C1 Tile adhesive and new building chemicals in China, for a best supplier and wholesaler of new building chemicals please go through: http://www.yunyanchina.com