YUNYANMIX Polyurea Coating is manufactured by YUNYAN company, YUNYANMIX is a well branded one of Top 10 for Polyurea Coating and new building chemicals in China, for a best supplier and wholesaler of new building chemicals please go through: http://www.yunyanchina.com

PRODUCT DESCRIPTION

Spray-type polyurea material is an elastomer material formed by the reaction of isocyanate component (referred to as A component) and amino compound component (referred to as R component). It is a new solvent-free and pollution-free green construction technology developed to meet the needs of environmental protection after the coating technology of low-pollution coatings such as water borne coating and powder coatings.

PRODUCT FEATURES

l Fast curing, 10 seconds gel, continuous spraying on facade and curved surface without sagging.

l 100% solid content, no volatile organic compounds, non-polluting green materials that meet environmental protection requirements.

l The coating is dense, seamless, and has strong penetration resistance.

l It has outstanding medium resistance and anti-corrosion performance, and can withstand the erosion of water, acid, alkali, salt, oil and other media.

l High mechanical strength, good elongation, hardness can be adjusted according to demand.

l It can withstand high and low temperature cyclic impact, and can withstand short-term high temperature impact.

l Excellent physical properties, good adhesion to various substrates.

l Good weather resistance. Outdoor long-term use without chalking, cracking or falling off.

l The construction speed is fast, and the single-machine single-day construction area is more than 1,000 square meters

l No maintenance is required, which saves expensive maintenance costs, one investment, and lifetime benefits.

SCOPE OF APPLICATION

l Roof concrete

l Anti-corrosion of steel structures such as cesspools, pipes, storage tanks, docks, steel piles and chemical storage tanks.

l Water park

l Mining Equipment

100% POLYUREA ARTIFICIAL COATING

PRODUCT DESCRIPTION

It has anti-corrosion, anti-penetration, high wear resistance, high-efficiency construction and outstanding mechanical properties.

SCOPE OF APPLICATION

l Practical occasions and industrial floors that require high wear resistance, high weather resistance and fast construction speed, such as water parks, sports stands, high-speed flyovers and colored roads.

l Grass, feed, textile, beverage, clothing, furniture, plastic, stationery, ceiling, automobile 4S shop and other manufacturing workshop painting

CONSTRUCTION GUILDLINE

1. Base surface treatment

It is treated by first sweeping and then cleaning. Water-soluble stains such as dust can be removed directly by low-pressure washing. Cleaning with detergents, weak alkaline solutions and other solvents, the residual solvent must be rinsed off after cleaning to avoid re-contamination of the engineering surface during the grinding process.

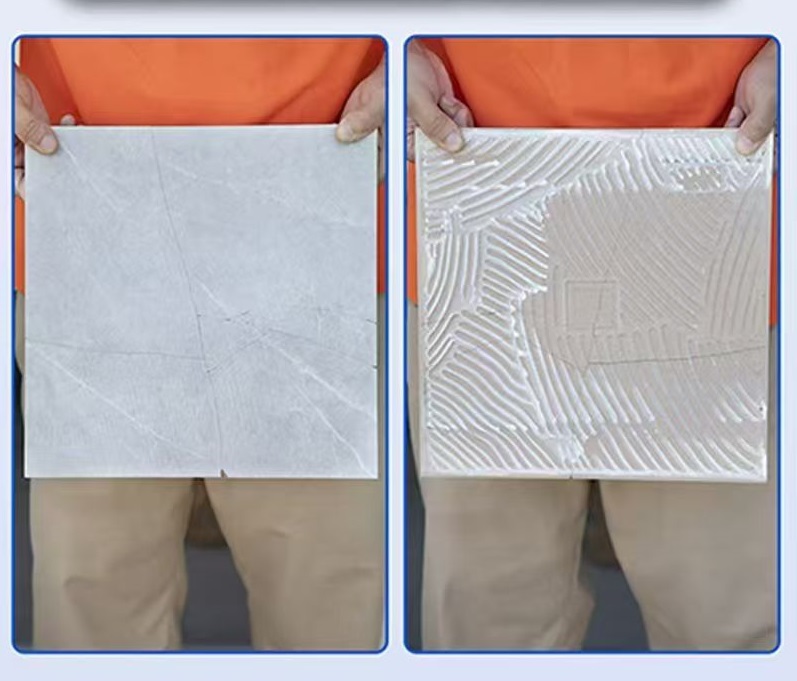

When the surface is uneven or loose after cleaning, use manual grinding or mechanical vacuum cleaning to treat it to improve the flatness of the engineering surface, which plays a key role in the appearance and durability of the polyurea coating.

2. Special primer construction

The special primer for polyurea is a base treatment agent for polyurea materials, which should be pre-coated on the base surface. It can close the capillary pores of the base surface, reduce the coating defects after spraying, and increase the adhesion between the polyurea coating and the base layer.

3. Repair polyurea putty (selected according to the wear of the base surface)

If the base surface is in good condition or there are no special requirements, the construction can be carried out directly; if the wear is serious or there are special requirements, the putty must be scraped before the polyurea coating is applied to ensure the smooth surface of the polyurea coating and increase the overall thickness .

Use polyurea special putty to repair and level the holes, honeycomb structure and defective holes. The larger defects are filled and compacted with polyurea mortar. After drying, scrape and apply polyurea special putty. After the putty is cured, use an electric grinding wheel to grind it. flat. If the batch scraping is uneven or too smooth, resulting in a long interval, it needs to be hardened and dried, and then be fully sanded and cleaned with a vacuum cleaner.

4. Polyurea coating construction

4.1 Construction technology of spraying polyurea

Calculate the amount of material used, and select the placement area of the spraying equipment according to the construction direction and area, in line with the construction path. Spray on the dry non-engineering interview for 5-10 seconds, and the engineering surface can be sprayed only after the coating quality meets the design requirements. Because the spray gun and the front end of the hose are not heated, the material temperature is low, the mixing and atomization effect is poor, and it is easy to cause bubbling. The same test is required every time the spray gun is fired. If there is a fault, it should be stopped immediately, and the test spray should be carried out again after the fault is eliminated, and the spray should be repeated after passing the test.

The spraying is carried out in the order of top, bottom and bottom, and the method of small area vertical and horizontal cross movement is carried out, and the moving speed is carried out according to the thickness of each layer of 0.35-0.50mm. The width of each spraying should be less than 1200mm, and the overlapping width between adjacent sprayings should be greater than 120MM. After the polyurea interface treatment agent is applied, it is re-sprayed to improve the interlayer bonding strength with the re-sprayed polyurea coating. The width of the re-spray should also be greater than 120MM. The adjacent base surfaces that are not one-time sprayed should be shielded. Protect and keep spray thickness consistent.

|

Working temperature(℃) |

Interval time (h) |

Re-coat requirement |

|

T≥15 |

>2 |

It should be treated with interface treatment agent before spraying |

|

≤2 |

Can be sprayed directly |

|

|

10<T<15 |

>3 |

It should be treated with interface treatment agent before spraying |

|

≤3 |

Can be sprayed directly |

|

|

T≤10 |

≥4 |

It should be treated with interface treatment agent before spraying |

When spraying the gun, stop the gun on a shelter or non-engineering surface. When the gun is stopped, the residual material is pushed out by the compressed air or valve stem in the mixing chamber, which is not a high-pressure fluid, and its mixing effect is also poor, which is easy to cause bubbling.

While spraying, it is necessary to clean up the pollutants brought in under the feet and pipes at any time, so as to avoid the garbage causing the quality not to meet the standard. This is very important and must be noted.

During the spraying process, the thickness of the coating should be tested at any time, and parameters such as pressure and temperature should be observed at any time, and on-site records should be made. The surface of the coating should be smooth, without sagging, pinholes, blistering and cracking; use a magnetic side thickness gauge to detect the thickness of the coating, and the thickness at the thinnest point shall not be less than 80% of the design thickness. When the thickness does not meet the requirements, or there are defects such as bubbling and shelling caused by incomplete preparations, supplementary spraying or repair with polyurea repair material is carried out according to the above regulations. Polyurea repair material is a manual polyurea coating used to repair the construction quality defects of polyurea coatings.

Spraying polyurea can achieve a smooth and even surface, and can also use its rapid curing characteristics to present a "pocket surface" effect through artificial granulation. Before the last coating is completely cured, adjust the spray distance, angle and flow rate to let the atomized paint fall freely on the engineering surface, so as to form particles of uniform size, get a rough particle surface, and play anti-slip and matting When granulating artificially, attention should be paid to the wind direction and wind force. The constructor should be at the upper air outlet, and the wind force should be lower than level 3 to reduce the falling of atomized particles to the construction personnel and equipment.

4.2 Manual polyurea construction technology

After careful inspection to confirm that the foundation has been treated, avoid construction during periods of intense sunlight exposure. Use thinner to adjust the paint to a suitable construction consistency, and use a special polyurea rake to evenly coat the project surface. Pay attention to the leveling effect. If there are still scraping marks, add more thinner to ensure the surface leveling, and make on-site records. After the polyurea coating is dried and solidified, the surface flatness is tested by the water accumulation method. If there is any granular debris or accumulation on the surface, it needs to be trimmed with a grinder or other tools before subsequent construction.

After each squeegee is dry and solid, the next squeegee can be carried out (generally about 10 hours, depending on the on-site weather conditions, the catalyst content can be appropriately increased or decreased), until the squeegee reaches the required thickness. When the thickness does not meet the requirements, or there are defects such as bubbling and shelling caused by incomplete preparations, repair with polyurea repair material according to the regulations. The specific operations are as follows:

1). Treat the surface of the repaired part first;

2). The repair material should be used and prepared immediately, stirred evenly, and should be used up before the initial setting period;

3). Defects such as bubbling and shelling with a continuous area greater than or equal to 0.5 square meters should be re-sprayed according to regulations;

4). Defects such as discontinuous bubbling and shelling with an area of less than 0.5 square meters should be repaired by hand.

5). The pinhole should be repaired with manual polyurea repair material.

5. Roller coated polyurea topcoat

Polyurea special topcoat is a coating to prevent the aging and discoloration of the polyurea coating, and is used to improve the anti-ultraviolet ability of the coating. When using, the dosage should be calculated, and the main agent and curing agent should be mixed in proportion and used as soon as possible after fully stirring. Using a special roller tool, apply the polyurea special surface coating evenly on the engineering surface, minimize the joint seam, and finish the coating within the specified time and pay attention to the connection of the front and rear groups. If impurities are found, they should be removed immediately.

EQUIPMENT REQUIREMENTS

1. The polyurea special spraying equipment consists of a spray gun and a high-pressure two-component polyurea special spraying machine, and is jointly operated by more than two spray gunners and equipment operators. The two operators should keep in touch at all times.

2. The working pressure of the main engine should be greater than 7.0Mpa, and the impact type mixed high-pressure spray type spray gun should be used to achieve uniform atomization. The pressure of the air compressor should be greater than 0.7Mpa, and the capacity should be greater than 0.85m3/min;

3. The volume ratio of the pumping pump of components A and B is 1:1, the heating temperature of the equipment heating device should be greater than 65℃, the heating temperature of the pipeline should be greater than 45℃, the temperature of the raw materials should not be lower than 15℃, and no dilution should be added. Do not mix the two components of raw materials outside the spraying equipment;

4. The equipment required for polyurea spraying is shown in the table below. The use of spraying equipment not approved by Guangdong Yunyan Company may have adverse effects on the final material properties, and the company will not be responsible for the resulting quality loss.

|

ITEM NO. |

MACHINE NAME |

UNIT |

QTY |

|

1 |

Polyurea special spraying machine |

PC |

1 |

|

2 |

Spray gun |

PC |

1 |

|

3 |

Pump |

PC |

2 |

|

4 |

Gun wash tank |

PC |

1 |

|

5 |

Air compressor |

PC |

1 |

|

6 |

Oil-water separator |

PC |

1 |

BASE SURFACE REQUIREMENTS

1. Moisture content of the base surface: the cement base surface must be coated when its moisture level is less than 8%, and the concrete base surface can be constructed even when its moisture level is not more than 6%, so the measurement of base surface moisture changes. be extremely important. The best way to measure the moisture of the base surface is the "rubber pad test", which is to tape at least 1MX1M polyethylene film to the concrete base surface, remove it after 24 hours, determine the amount of condensation water, and thus determine the rising moisture of the base surface Spend.

2. The compressive strength of the base surface: the compressive strength of the engineering surface should not be lower than 25N/mm2 (3500psi). In order to meet the load-bearing requirements of the equipment, the thickness of the base surface should be more than 20cm, and the roughness of the base surface should be iron plate light. 0.8-1.6.

3. The flatness of the base surface: the base surface is flat, without unevenness, honeycomb pitted surface, cement lumps, within any 2㎡, the flatness shall not be greater than 2MM;

4. The base surface has no defects: the base surface is firm and strong, and the phenomenon of mortar shelling is avoided. It is best to pour the concrete layer together with the mortar leveling layer; if the concrete layer is rammed first, the thickness of the mortar layer should not be less than 4cm.

ENVIRONMENTAL REQUIREMENTS:

During construction, the temperature should be kept between 5-40℃, and construction should not be performed or prohibited below 5℃. The temperature of the base surface should be more than 3℃ higher than the dew point temperature; The wind force should be less than or equal to level 3; in order to ensure that the indoor temperature difference changes little during construction, and to prevent dust, debris, and flying insects from entering into pollutants, the construction must be carried out after the doors and windows of the building are installed; avoid cross-construction, and no idlers are allowed. into the construction site to prevent damage to the base surface.

COOPERATION MATTERS :

1. Matters needing cooperation before construction

Confirm the construction area and construction specifications (color and construction area); provide 380V, 100A supporting power supply and 16² or more hard core cables. Determine the power connection point; provide lighting equipment. In case of night construction, night lighting facilities shall be provided; solve on-site water and drainage problems, such as water sources, water pipes, drainage ditches, etc.; The warehouse of raw materials and equipment requires an area of more than 30㎡, and should be kept in a cool, dry, ventilated, rain-proof, temperature of 5-40 ℃, and should meet the storage requirements of the product instruction manual.

2. Matters needing cooperation during construction

Personnel entry and exit control in construction area; waste storage area; on-site supervisor and coordinator.

3. Matters needing cooperation after construction

Personnel entry and exit control in the maintenance area; on-site cleaning and return of loaned items; actual area measurement and acceptance.

MAINTENANCE

1. Do not abuse machinery: avoid the use of vehicles such as steel wheels, and do not have excessive traffic and loads. Take care to avoid scratches when in contact with the substrate.

2. Surface cleaning: When the base surface is contaminated by chemicals, it is generally scrubbed with water, and the difficult-to-clean stains can be cleaned with a cleaning agent. Industrial degreaser and descaling agent can also be used. It is recommended to use a solvent such as xylene for cleaning, and then Rinse with water and pay attention to ventilation;

3. The topcoat protection layer in the system is to be wear-resistant and weather-resistant. After the polyurea is applied, the surface will wear for a long time. Therefore, in order to achieve long-term protection requirements, the surface needs to be provided with a separate wear-resistant and weather-resistant layer;

4. Fire protection requirements: This system not only effectively protects the main waterproof polyurea coating, allowing it to exert its excellent performance for more than 30 years, but also provides fire resistance, such as when people smoke, cigarette butts will not damage the polyurea layer.

5. Maintenance: Just like a car, an excellent system does not mean that maintenance is not required, but maintenance and maintenance are also required. Maintenance after 10-20 years is generally only to maintain the wear-resistant and weather-resistant surface layer of the surface. Carry out maintenance while the polyurea material is not damaged.