PRODUCT DESCRIPTION

Single component manual polyurea is an aliphatic polyurea waterproof coating material, which has excellent bonding strength with the concrete base surface. Because of its unique chemical structure, product excellent high strength, high toughness and acid and alkali resistance characteristics make the coating has tensile resistance, wear resistance and impact resistance, effectively prevent concrete ground temperature difference, stress cracking coating is broken, especially suitable for building roof, pool, road bridge, water conservancy dam concrete surface durability in waterproof coating.

FEATURES AND BENEFITS

Ø High solid content, low VOC emission;

Ø The construction method is simple, and can be brushed, rolled, air spraying or high pressure without gas spraying;

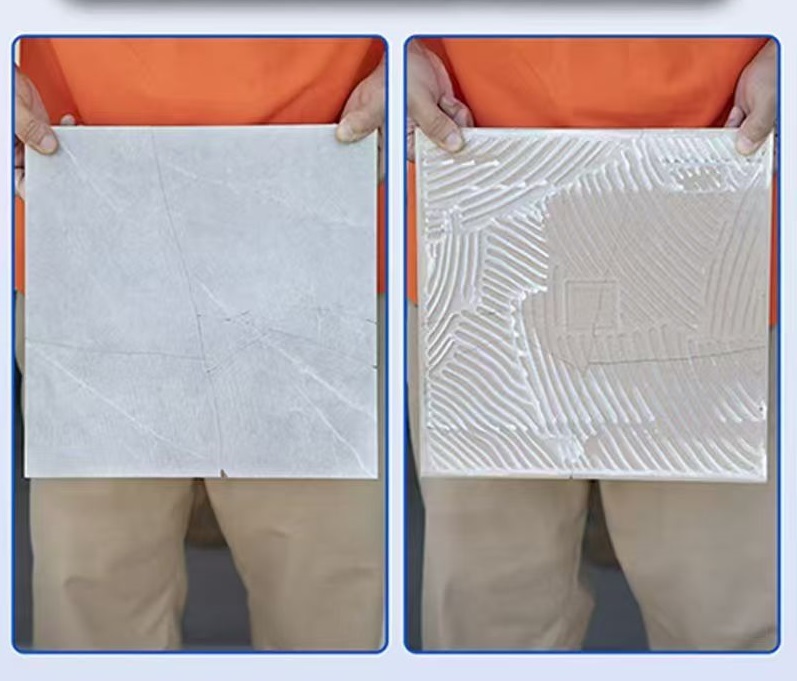

Ø Good wear resistance, impact resistance, scratch resistance, cracking prevention and other physical properties;

Ø Excellent ultraviolet light resistance and waterproof performance;

Ø Excellent chemical corrosion resistance, can withstand a certain concentration of acid, alkali, salt, oil, organic solvent and other corrosion;

Ø Excellent adhesion, can quickly and firmly bond to the concrete, steel structure, wood, glass fiber and other substrate surface;

Ø Wide use temperature, can be used in-40℃ ~120℃ environment;

Ø The characteristics of the single component make the operation simple and convenient, without matching, and reduce the labor cost.

WHERE TO USE

Building floor (sky), exterior wall, basement, pool, bridge pavement, dam and other repair waterproof.

HOW TO USE

Inorganic bottom coating + high permeability epoxy (bottom coating can be used in two coating and one cloth) + single component aliphatic manual polyurea

Construction technology

1, the base surface clean, the base surface dry water without oil, the crack should be filled first;

2, the base surface scraping coating inorganic bottom coating leveling, using 2 coating 1 cloth construction;

3, after the inorganic bottom coating is solidified, coating (rolling coating) single component manual polyurea coating, according to the needs of coating design, coating 2~3 times, to the dry film thickness requirements, each construction interval should not exceed 24 hours, the fine structure to strengthen the waterproof layer.

Package: 10 kg / barrel

Validity of storage: 10 months (stored in dry ventilation place)

TECHNICAL PARAMETER

|

Item |

Type I index |

Type II index |

|

solid content /% |

≥80% |

≥85% |

|

Semi dry time/h |

≤2 |

≤2 |

|

Final dry time/h |

≤5 |

≤5 |

|

Tensile strength/Mpa |

≥10 |

≥15 |

|

Elongation rate/% |

≥300 |

≥200 |

|

Hardness (shore A) |

≥75 |

≥80 |

|

Low temperature bending/% |

-40 |

-40 |

|

Wear resistance / (750g / 500r) / mg |

≤30 |

≤30 |

|

Density g/cm3 |

1.05 |

1.1 |

YUNYANMIX Polyurea waterproof coating is manufactured by YUNYAN company, YUNYANMIX is a well branded one of Top 10 for polyurea waterproof coating and new building chemicals in China, for a best supplier and wholesaler of new building chemicals please go through: http://www.yunyanchina.com