Product Description:

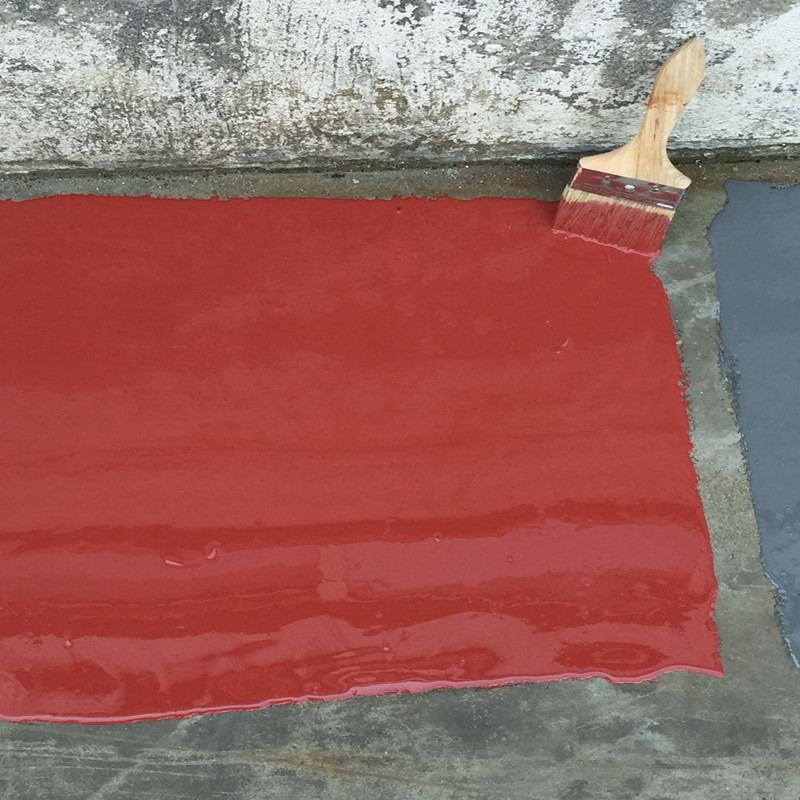

it is a polyurethane membrane,single-component, pigmented, colored, semi-rigid, resistant to UVA rays, of application and cold drying used for the protection of other exposed waterproof membranes in excess to bad weather. It dries by reaction with the soil and the air humidity.

Product Advantages:

Easy application (roller or airless spray machine)

• Resistant to constant abrasion and traffic

• An easy-to-clean glossy finish is achieved.

• Color stable

• Resistant to stagnant water

• Maintains its mechanical properties at temperatures from -30℃ to +90℃.

• Frost resistant.

Where to use:

• Exposed areas in car parks, bridges, soccer field stands,football

• Areas with lots of people and light cars

• Highly exposed surfaces

• Also used for the encapsulation of the fibers of the asbestos cement

Preparations:

Good surface preparation is essential for an optimal and long-lasting final finish.

The surface must be clean, dry and free of any type of contamination, factors that can affect the adhesion of the membrane. The maximum humidity should not exceed 5%.

WARNING: Do not clean the surface with water.

Unit consumption:

400-600 gr. /m2 in two layers. This consumption is based on practical application with a roller on a smooth surface in optimal conditions. Factors such as surface porosity,temperature, humidity, application method and finish may require other consumption.

How to use:

Stir well before use. Apply YY-924 top coat on polyurethane waterproofing membrane with a roller or airless in two coats.

Allow to dry for 3 to 6 hours (no more than 8 hours) between the two coats.

Technical Information:

|

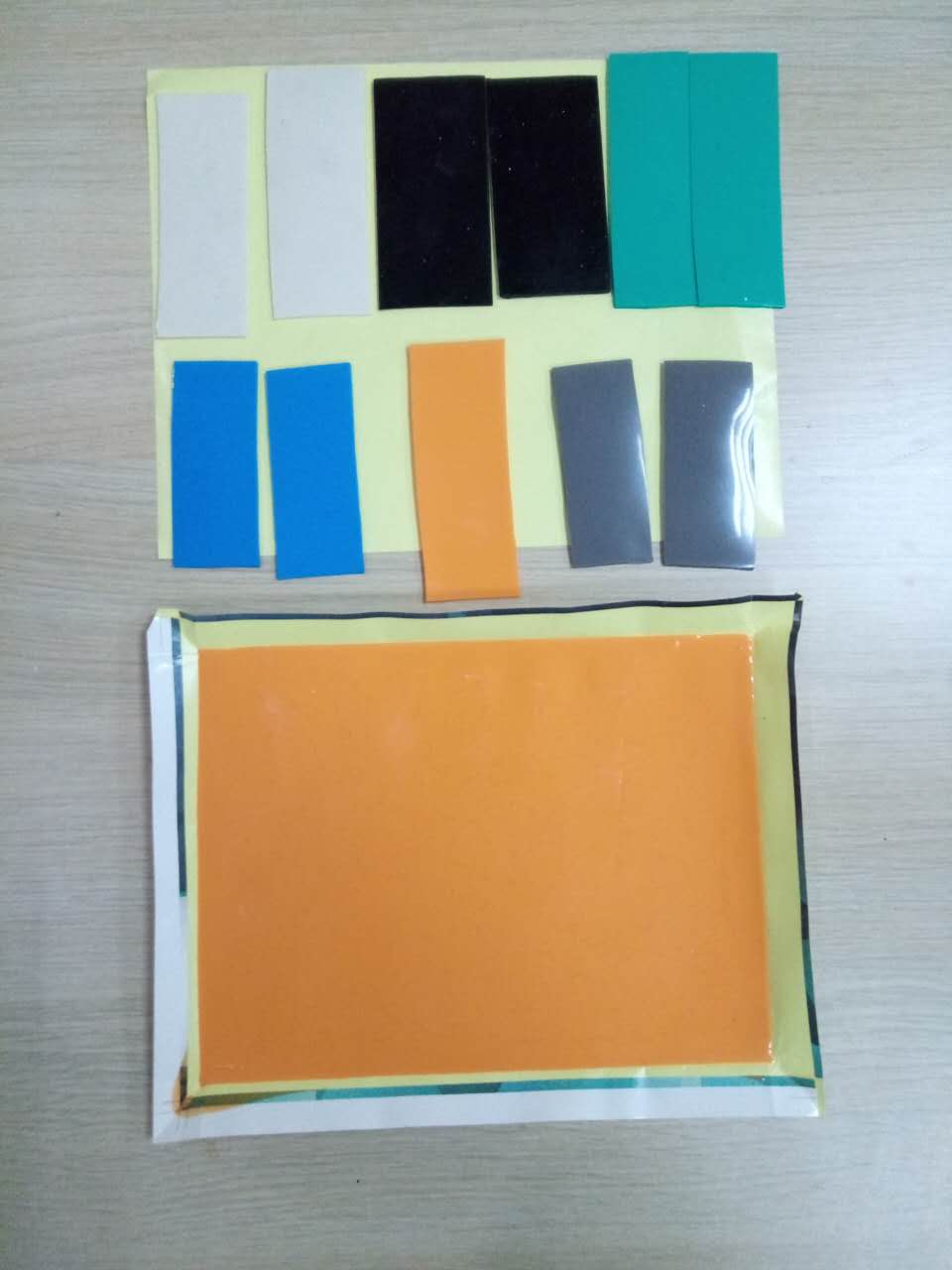

Color |

supplied in grey, white, red and green. Other RAL colors can be supplied on request. |

|

Elongation rate ASTM D 412 |

>150% |

|

Hardness (SHORE D Scale) ASTM D 2240 |

55 |

|

Status |

Solvent base liquid |

|

Component |

Single part |

|

Tack free time |

4 hours |

|

Light pedestrian traffic |

24 hours @25℃ |

|

Final drying time |

7 days |

|

Tensile Strength (ASTM D2370) |

>250 psi |

|

Resistance to water pressure DIN EN 1928 |

No Leak (1m water column, 24h) |

|

Service temperature |

-30℃-+90℃ |

Package : 20kg/18L Barrel

Precautions: Keep the applying surface dry and clean. Stir firmly before applying. Avoid to operate in high moisture weather conditions.The product must be stored in a cool and dry place for not more than 9 months. The product must be protected from humidity and direct sunlight. Storage temperature should be 5℃ to 40℃. The products must remain in their original container, unopened, retaining the name of the manufacturer, the designation of the

product, the batch number and the security measures specified on the label.

Packaging details: shrink wrapped packed on plywood pallet

Disposal:

In the interest of the environment, please empty all barrels completely & in accordance with local regulations.

YUNYANMIX polyurethane waterproof coating is manufactured by YUNYAN company, YUNYANMIX is a well branded one of Top 10 for polyurethae waterproof coating and new building chemicals in China, for a best supplier and wholesaler of new building chemicals please go through: http://www.yunyanchina.com