YUNYANMIX water based polyurethane floor paint is manufactured by YUNYAN company, YUNYANMIX is a well branded one of Top 10 for water based polyurethane floor paint and new building chemicals in China, for a best supplier and wholesaler of new building chemicals please go through: http://www.yunyanchina.com

Product Descriptions:

Water-based polyurethane for floors is a protective, clear-drying finish made with synthetic resins and water. It's a popular choice because it has a quick drying time, low odor, and is eco-friendly with fewer volatile organic compounds (VOCs) than oil-based versions. Water-based polyurethane forms a durable, clear coat that protects wood floors from scratches and abrasions without adding a yellow tint.

Product Features:

1. Non VOC and non formaldehyde

2. Excellent elasticity and toughness

3. Excellent water resistance and solvent resistance

4. Excellent adhesive with polar and non-polar materials

5. Stable while mixed with other water-based resin and additives

Scope of Application

1. Water based paint/coating

2. Textile coating

3. Industrial coating

4. Printing ink

5.Plastic coating etc.

Usage in theory: 0.2kg/㎡ (For two coats).

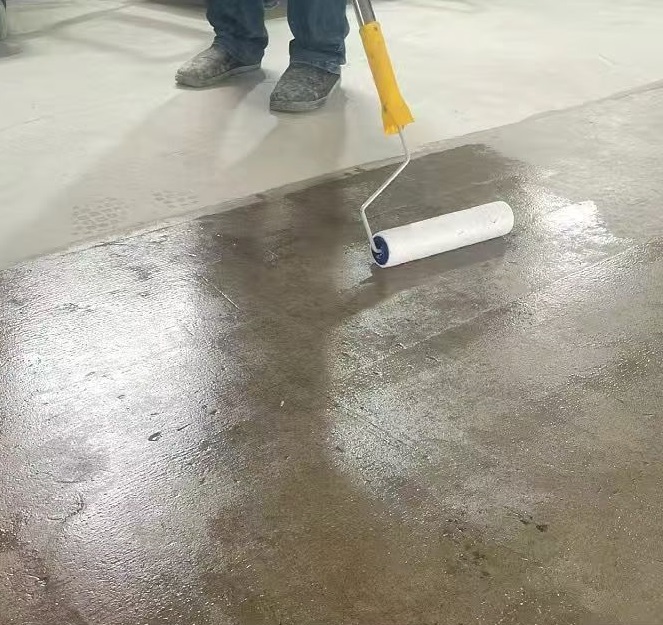

Construction: By roll or brush

Packing : YY-190WA 16kg/Bucket ; YY-190WB

4kg/Bucket

Stored in dry, shade and ventilated warehouseTechnical Data:

Status

Double component liquid form

Color

Transparent

Construction

By brush or roll

Coating appearance

≥By Passed GB/T 22374-2008

Initial setting time

1h

GB/T 22374-2008

Final setting time

8h

GB/T 22374-2008

Adhesion force

grade

≤1

GB/T 22374-2008

Shore D Hardness (pensil scratch)

≥75

GB/T 22374-2008

Wear resistant test

750g/500r

g

0.027

GB/T 22374-2008

Tensile adhesion strength

Mpa

2.45

GB/T 22374-2008

Water resistant test

168h

Passed GB/T 22374-2008

Chemical resistant test

#120 solvent oil,72h

Passed GB/T 22374-2008

Impact resistant test

grade 1 Passed GB/T 22374-2008

Benzene

g/kg

<0.01

GB/T 22374-2008

Led

mg/kg <1.0

GB/T 22374-2008

Cadmium

mg/kg <0.5

GB/T 22374-2008

Chromium

mg/kg <0.5

GB/T 22374-2008

Mercury Hg

mg/kg <0.1

GB/T 22374-2008

Shelf life

9-12 months

Condition on site

5-40℃

HOW TO MIX:

1ST time diluted with 30% water and second time with 10% water.

HOW TO APPLY:

Applied by a roller

Safety Notice:

This product is only for professional use. Use this product with care. Do not swallow before and

during use. Swallowing is harmful or fatal. If swallowed, seek medical advice immediately.

Avoid inhaling solvent vapor or paint mist, and skin and eyes must not touch this product. This

product can only be applied in a well-ventilated condition. In narrow places or where there is no

air circulation, strong ventilation must be provided. Always take precautionary measures

against fire and explosion.