YUNYANMIX Water Borne Epoxy Floor Paint is manufactured by YUNYAN company, YUNYANMIX is a well branded one of Top 10 for Water Borne Epoxy Floor Paint and new building chemicals in China, for a best supplier and wholesaler of new building chemicals please go through: http://www.yunyanchina.com

Product Descriptions:

It is made with NEH hybrid resin and special water-based curing agent, with special processing technology.Water based epoxy floor paints have another distinct advantage over solvent and solvent free floor paint materials, which is that whenever floor repainting and over-coating is eventually necessary, then only minimal surface preparation (cleaning) of the existing floor

coating is necessary.

Product Features:

1. Anti-acid and anti-alkali, chemical corrosion resistance.

2. High strength, wear-resistance.

3. Antimicrobial, long lasting service life for 10 years.

4. Anti-slip

5. Eco product, no odor and user friendly.

Scope of Application

It is suitable for warehouse,garage,airport, subway station, dining room, lounge, office area, food production workshop and the hospital, the school laboratory, etc. (indoor use only)

Usage in theory: 0.25kg/㎡ (For two coats).

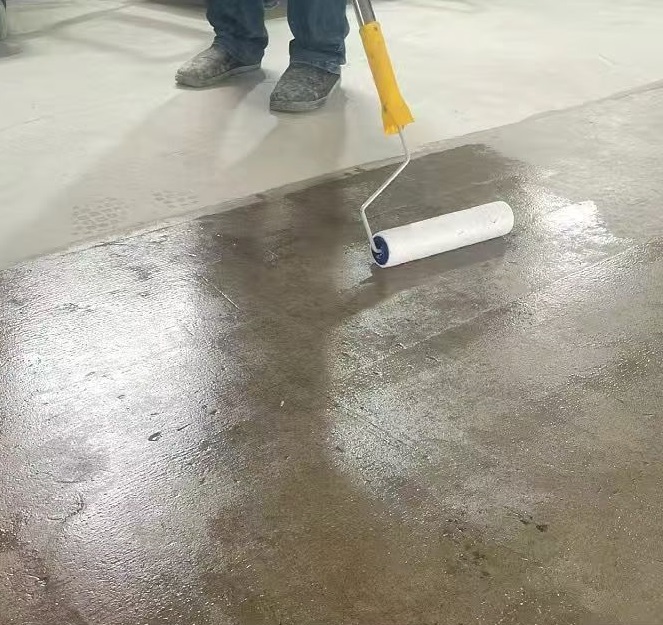

Construction: By roll or brush

Material: Epoxy based materials

YY-172A

|

|

Chemical Name |

CAS No. |

EC No. |

Concentration |

|

A |

1-methoxy-2-propanol |

107-98-2 |

--- |

5% |

|

Fatty amine adduct |

67846-33-7 |

--- |

20% |

|

|

|

||||

|

|

Water |

7732-18-5 |

|

15% |

|

|

Titanium Dioxide |

13463-67-7 |

|

10% |

|

|

talcum powder |

14807-96-6 |

|

8% |

|

|

Polydimethylsiloxane |

9006-65-9 |

|

1% |

|

|

Silicon powder |

7440-21-3 |

|

41% |

YY-172B

|

|

Chemical Name |

CAS No. |

EC No. |

Concentration |

|

B |

Bisphenol A epoxy resin |

25068-38-6 |

--- |

90% |

|

Glycidyl ether 12~14 alkyl ether |

68609-97-2 |

--- |

10% |

Packing : YY-172A 20kg/Barrel ;

YY-172B 5kg/Barrel

Technical Data:

|

Status |

Double component |

|

Color |

Customized |

|

YY-172A : YY-172B: water |

4KG:1KG:0.5L |

|

Construction |

By brush or roll |

|

Coating appearance |

≥By Passed |

|

Initial setting time |

≤8h |

|

Final setting time |

≤2d |

|

Adhesion force grade |

≤1 |

|

Tensile adhesion strength Mpa |

≥2.0 |

|

Moh’s hardness |

≥2H |

|

Wear resistant test 750g/500r g |

≤0.06 |

|

Compressive strength Mpa |

≥75 |

|

Water resistant test 168h |

Passed |

|

Alkalic resistant test 20% NaOH,72h |

Passed |

|

Acid resistant test 10% Sulfuric acid,48h |

Passed |

|

Oil resistant test 120# solvent oil 72h |

Passed |

|

Impact resistant test |

Passed |

|

Shelf life |

12 months |

|

Condition on site |

5-40℃ |

Safety Notice:

This product is only for professional use. Use this product with care. Do not swallow before and during use. Swallowing is harmful or fatal. If swallowed, seek medical advice immediately. Avoid inhaling solvent vapor or paint mist, and skin and eyes must not touch this product. This product can only be applied in a well-ventilated condition. In narrow places or where there is no air circulation, strong ventilation must be provided. Always take precautionary measures against fire and explosion.