Description

It is a high quality elastic adhesive/sealant based on silane modified polymer (SMP) technology, with excellent adhesion, weather resistance and durability. After curing, it forms a stable rubber elastomer with excellent adhesion to the substrate.

Product Feature

l Good adhesion can be obtained without primer on common substrates.

l Excellent UV resistance and aging resistance.

l High modulus, high elastic recovery rate, excellent bonding and durability, low shrinkage after curing.

l -40℃ to +90℃ maintain long-term flexibility.

l Neutral, odorless, and cured quickly.

l Environmental protection, no formaldehyde, benzene, benzene and other volatile organic compounds, no solvent, isocyanate, low VOC.

l No pollution to the substrate.

l Good paintability, good bonding compatibility with a variety of paint coatings, no pollution to the paint after painting (given the complexity and diversity of paint systems, it is recommended to conduct compatibility tests before use)

Scope of Application

l Can be used for the bonding and sealing between panels or between panels and keels, such as various wood panels, Ettenite panels, fiber cement panels, ALC (autoclaved light concrete) panels, etc.

l Adhesion and sealing of various materials waterproof tarpaulin.

l Can be used for most building materials such as metal, plastic, concrete,wood flooring and other materials bonding and sealing.

l Suitable for metal structures, such as fume hood, air conditioning, warehouse, box construction of various materials between various gaps in waterproof sealing, as well as welding, joint parts of elastic sealing.

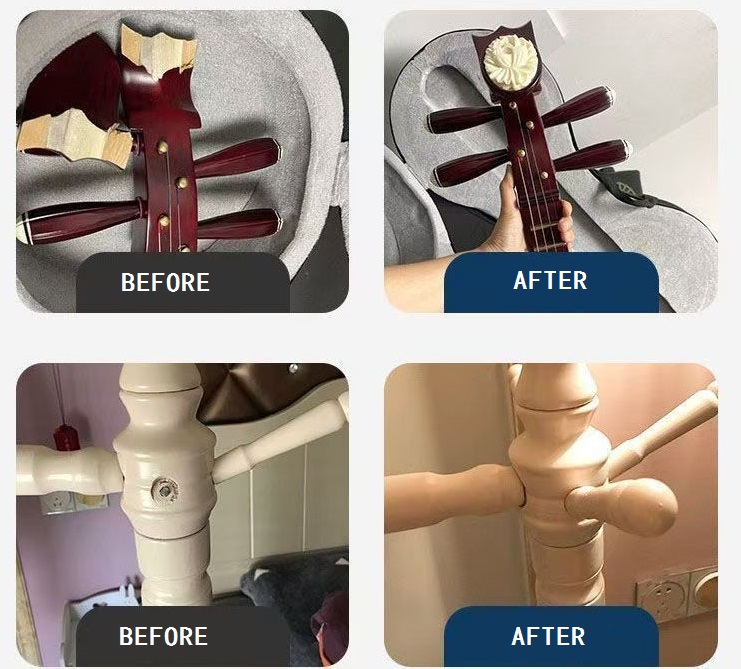

l Extensively used in advertising signs, glass display cases installation, home decoration, art bonding and sealing, etc.

l Under normal circumstances, the surface of a clean, dry substrate without dust and oil can be well attached without primer, such as aluminum, stainless steel, galvanized steel, zinc, copper, painted gold

l Glass, PVC, fiberglass, painted wood, etc., for not

l The treated polyethylene and Teflon materials remain free from adhesion. For bonding with various substrates, particularly rubber, plastic, and coating materials, pre-application testing of adhesion compatibility is essential due to material diversity and variations. We recommend consulting our technical service engineers for adhesion/cohesion compatibility testing prior to application to ensure compliance with practical operational requirements.

Technical Data:

|

Basic material |

silane modified polymer(SMP)

|

|

Curing mechanism |

moisture curing

|

|

Drying time: |

10-30 minutes

|

|

Solvent content |

0%

|

|

Isocyanate content |

0%

|

|

Standard colors: |

black, white and gray

|

|

Density 23℃GB T 13477.2 |

about 1.52g/ml

|

|

The sag is vertical GB/T 13477.6 |

1 mm

|

|

24 hours of curing depth |

2-3 mm

|

|

Extrusion, ml/min |

850 |

|

Construction temperature |

+5℃ to +40℃

|

|

Tolerable temperature |

-40℃ to +90℃

|

|

tensile strength GB/T528 |

0.8 MPa |

|

Elastic recovery rate % |

85% |

|

mass loss rate %

|

1.5 |

HOW TO USE

It can be easily extruded with a manual or pneumatic glue gun at +5℃ to 40℃. For sealing applications, YY-119 should be applied on the surface of the glue

Before the skin is formed, (the time of bonding skin will vary under different environmental humidity and humidity, for example: at 23℃/50% R.H., the time of bonding skin is about 20 minutes), the surface of the glue should be smooth and trimmed with a scraper or a brush. The scraper or brush can also be wetted with soap water to perform the surface of the glue

The surface should be trimmed, but avoid soap water seeping between the bonding substrate and sealant, as this may cause bonding failure. Clean tools or remove residual that is not dry by using a clean, colorless cloth moistened with isopropanol.

PACKAGE:

600ml sausage-shaped package; 300ml rigid tube package

The package can be stored for 12 months in a cool and dry environment of 5℃-35℃. Under normal circumstances, the product performance will not be affected by ordinary transportation.

YUNYANMIX Wood MS Glue is manufactured by YUNYAN company, YUNYANMIX is a well branded one of Top 10 for Wood MS Glue and new building chemicals in China, for a best supplier and wholesaler of new building chemicals please go through: http://www.yunyanchina.com