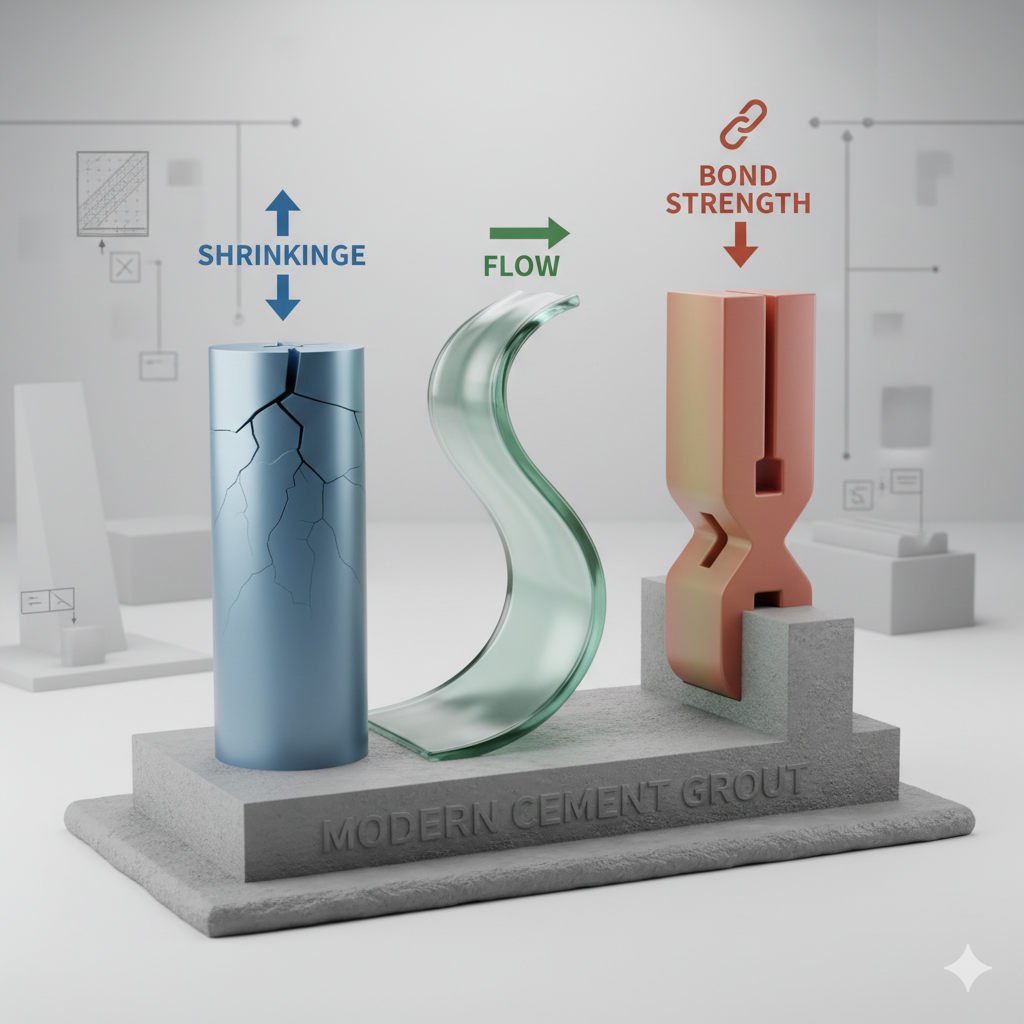

Shrinkage, Flow, and Bond Strength: The Three Pillars of Modern Cement Grout

In construction, cement grout is more than just a filler—it is the invisible framework that locks every tile, stone, and panel into lasting alignment. Yet when grout fails, it rarely does so quietly: cracks, voids, or discoloration can surface within weeks, even on otherwise perfect installations. Behind each failure lies a simple truth: shrinkage, flow, and bond strength must exist in balance.

Modern projects—especially those using large-format tiles, sintered slabs, or façade cladding—demand a new generation of cement grout engineered around these three pillars.

1. When Grout Shrinks, the Structure Moves

Shrinkage is the most underestimated threat in tiling. As cement grout cures, it naturally loses moisture and contracts. When that contraction exceeds its internal strength, micro-cracks form along joint edges, allowing water, dust, and bacteria to penetrate.

In high-traffic spaces or outdoor settings, those micro-cracks expand, leading to grout detachment and joint discoloration.

Common causes of grout shrinkage include:

-

Overwatered mixes that increase drying stress

-

Low polymer content or poor binder ratio

-

Rapid evaporation in hot or windy environments

-

Inadequate curing protection

To counter this, advanced formulations now incorporate anti-shrink polymers and microsilica to maintain dimensional stability throughout curing.

2. Flow: Precision Filling for Tight Joints and Complex Surfaces

Perfect grout flow is not about liquidity—it’s about controlled mobility.

A modern grout must fill every void evenly, wrap around tile edges, and achieve complete contact without segregation or bleeding.

Too thick, and it won’t spread uniformly.

Too thin, and it loses body, strength, and color consistency.

Optimized Flow Parameters for Professional Grout

| Property | Ideal Range | Function |

|---|---|---|

| Flow Value | 120–160 mm | Ensures full cavity filling |

| Working Time | 30–45 min | Allows precise application |

| Water Demand | 18–22% | Maintains mix stability |

| Segregation Resistance | High | Prevents color streaks |

| Thixotropy | Moderate | Balances flow & resistance |

This engineered balance ensures smooth joints even in vertical applications like wall tiles and façades.

Manufacturers like YUNYAN adjust rheological behavior to remain workable for installers while preventing slumping under gravity.

3. Bond Strength: The Silent Guarantee Behind Every Tile

A grout joint may only be a few millimeters wide, but its role in bonding adjacent tiles is critical.

Bond strength determines how well the grout holds under thermal expansion, foot traffic, and substrate movement.

Inadequate bonding can lead to:

-

Tile edge chipping from differential stress

-

Joint powdering under abrasion

-

Water seepage weakening adhesive layers below

Modern cement grout enhances adhesion using polymer modification, creating flexible molecular bridges between the tile edge and substrate.

This design allows a slight degree of elasticity while preserving structural integrity—a key factor in both interior floors and exterior façades.

4. Real-World Scenarios: Where Balance Defines Performance

The three pillars—shrinkage, flow, and bond—play differently across various environments.

Below is how they interact in real projects:

| Application | Critical Property | Performance Focus |

|---|---|---|

| Large-format floors | Low shrinkage | Prevents joint cracking under thermal movement |

| Commercial interiors | Flow | Fast, uniform coverage for productivity |

| Kitchens & bathrooms | Bond strength | Resistance to water ingress and detergent exposure |

| Façade cladding | All three | Dimensional stability + adhesion under temperature cycles |

| Tile-over-tile renovation | Flow & bond | Smooth leveling and adhesion over non-porous base |

Each condition emphasizes one property more than others, but the system only endures when all three work together.

5. Selecting the Right Cement Grout for Your Project

Choosing the right cement grout is not about brand—it's about matching formula to environment.

Here’s a simple professional guide:

-

Indoor tiles (standard rooms): Normal shrinkage control, standard flow

-

High humidity (bathrooms, kitchens): Polymer-modified grout with low absorption

-

Outdoor or façade: High bond strength + low shrinkage, weather-resistant

-

Heavy traffic commercial floors: Reinforced grout with superior abrasion resistance

-

Large-format or sintered slabs: Flow-optimized, flexible polymer grout

When performance specifications such as compressive strength (>30 MPa) or water absorption (<3%) appear in technical sheets, they’re not just numbers—they indicate real-world reliability.

6. The Evolution of Cement Grout Formulation

Old formulations focused on filling space.

Modern cement grout aims to engineer durability—to resist time, temperature, and tension.

With ongoing innovation in polymer chemistry and fine aggregates, new-generation systems can self-compensate shrinkage, improve adhesion to non-porous surfaces, and maintain uniform curing color.

This transition marks the industry’s shift from “material use” to “material design,”

and brands like YUNYAN continue refining this balance for both small-scale tiling and architectural façade systems.

Filling Gaps

The performance of cement grout defines not only how a project looks on day one but also how it performs after years of environmental exposure. Shrinkage, flow, and bond strength—these three unseen parameters—decide whether a tiled surface becomes a lasting structure or a maintenance issue.

For engineers, designers, and contractors seeking verified solutions, more product insights and technical guidance are available through YUNYAN’s official site.

For project-specific consultation or specification requests, reach out via the contact page to ensure your next installation is built on balance, precision, and reliability.