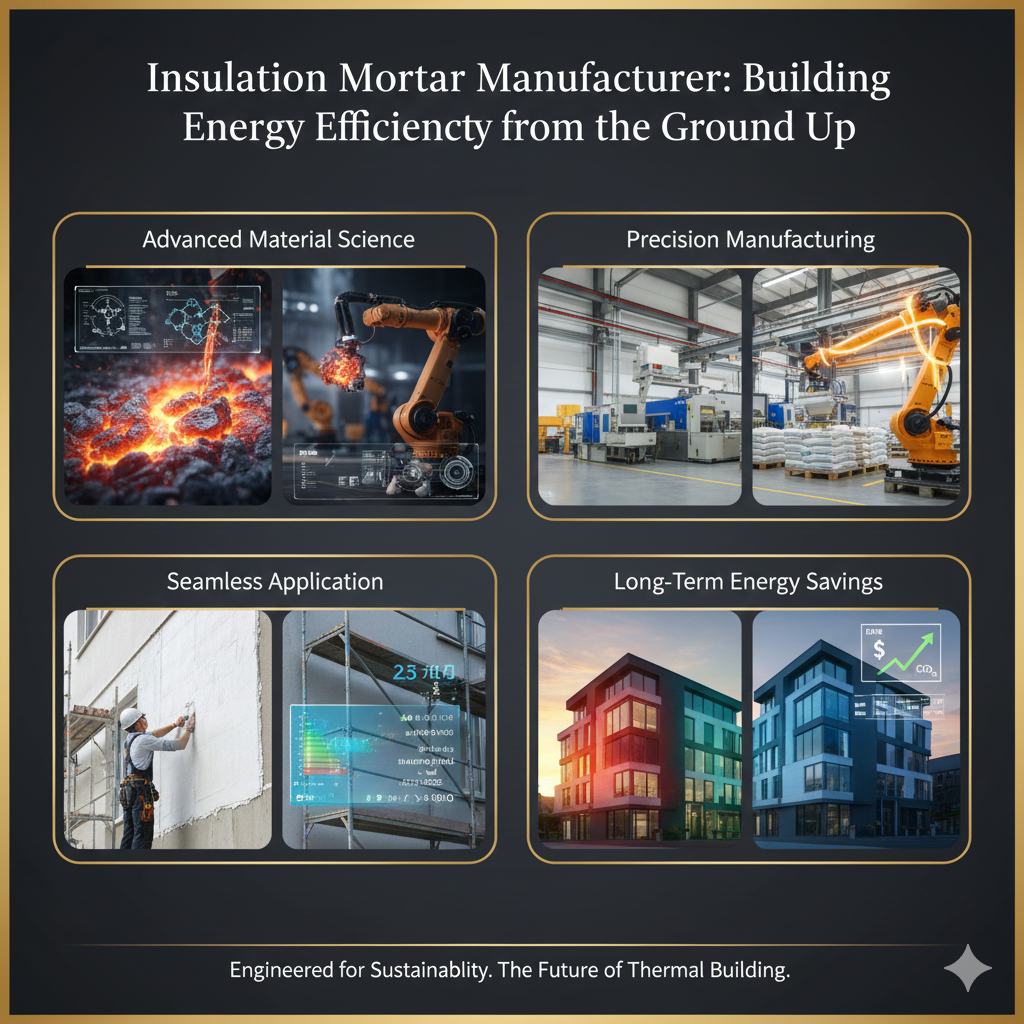

Insulation Mortar Manufacturer: Building Energy Efficiency from the Ground Up

Every degree of indoor comfort starts with what’s inside the wall.

Traditional renders protect against rain and cracks—but they let heat escape freely.

In a world where energy efficiency defines sustainability, insulation mortar has become a new construction essential, combining thermal resistance, adhesion strength, and longevity in one integrated solution.

1 | The Hidden Cost of Energy Loss Through Walls

More than 30% of building energy is lost through poorly insulated walls.

For property owners, this means higher electricity bills, condensation issues, and unstable indoor temperatures.

Common pain points include:

-

Thermal bridging between structural layers.

-

Cracks due to temperature expansion differences.

-

Poor adhesion between insulation boards and plaster.

-

Mold formation from trapped moisture.

The solution isn’t thicker paint—it’s a scientifically engineered mortar layer that stabilizes both temperature and structure.

2 | What Makes Insulation Mortar Different

Unlike regular plaster, insulation mortar integrates lightweight aggregates, thermal barriers, and polymer binders to balance heat retention with durability.

| Ingredient | Function | Performance Contribution |

|---|---|---|

| Expanded Perlite / EPS Beads | Lightweight filler | Reduces thermal conductivity (λ ≤ 0.08 W/m·K) |

| Cementitious Binder | Structural base | Provides compressive strength ≥ 3 MPa |

| Polymer Additives | Adhesion & flexibility | Prevents cracking and detachment |

| Hydrophobic Agents | Moisture resistance | Maintains thermal efficiency in humid climates |

| Cellulose Fibers | Micro-reinforcement | Increases tensile strength and bonding stability |

The result: a breathable, energy-saving surface that bonds seamlessly with concrete, brick, or insulation boards.

3 | Comparison: Traditional Render vs. Insulation Mortar

| Property | Traditional Render | YUNYAN Insulation Mortar |

|---|---|---|

| Density | ~1.8 g/cm³ | 0.5–0.8 g/cm³ |

| Thermal Conductivity | 0.9–1.0 W/m·K | ≤ 0.08 W/m·K |

| Compressive Strength | High but brittle | Balanced flexibility |

| Adhesion to Base | Moderate | > 0.3 MPa (excellent) |

| Crack Resistance | Poor under temperature cycles | Reinforced with polymers |

| Durability | 5–8 years typical | 15 + years (tested) |

Conclusion:

Insulation mortars reduce wall heat transfer by more than 80%, extending building life and lowering HVAC energy consumption.

4 | Inside YUNYAN’s Manufacturing Process

Each batch of YUNYAN insulation mortar is engineered for consistent performance across diverse climates and export standards.

1️⃣ Raw Material Selection – Perlite graded for bulk density 60–80 kg/m³.

2️⃣ Precision Batching – Automated dosing ensures ±0.5% ratio accuracy.

3️⃣ Polymer Integration – High-shear mixing for uniform distribution.

4️⃣ Moisture Control Packaging – Triple-layer bag prevents humidity absorption.

5️⃣ Quality Testing – Thermal conductivity, adhesion, and shrinkage ratio verified under EN 998-1 and ASTM C1329.

YUNYAN’s OEM program allows custom formulations (e.g., anti-crack, fast-dry, or hydrophobic versions) for different regional climates and construction systems.

5 | Application Process: From Wall Prep to Thermal Seal

| Step | Description | Key Control |

|---|---|---|

| 1. Surface Preparation | Remove dust, loose plaster | Base moisture ≤ 6% |

| 2. Mixing | Add 24–26% clean water | Use slow-speed mixer |

| 3. Application | Apply 2–3 layers (8–15 mm total) | Avoid over-thick coating |

| 4. Leveling & Troweling | Maintain even surface | Prevent voids for thermal continuity |

| 5. Curing | Keep moist for 48 h | Avoid direct sunlight |

For façade systems, it can be combined with mesh reinforcement and finish coat for long-term structural protection.

6 | Typical Application Scenarios

| Project Type | Challenge | YUNYAN Solution |

|---|---|---|

| Residential Buildings | Energy loss through walls | EPS-perlite thermal mortar |

| High-Rise Projects | Weight load reduction | Lightweight polymer mortar |

| Cold Regions | Freeze-thaw durability | Anti-crack flexible mortar |

| Coastal Construction | Salt & moisture exposure | Hydrophobic formula |

| Retrofit Renovation | Uneven substrate | Fiber-reinforced high-adhesion mortar |

Each scenario benefits from tailored performance that balances insulation, adhesion, and structural stability.

7 | Energy, Cost, and Sustainability Benefits

-

Reduces energy consumption by 25–40% per building.

-

Decreases CO₂ emissions through better insulation.

-

Provides longer maintenance cycles—no repainting or patching for years.

-

Uses non-toxic, recyclable aggregates.

-

Complies with LEED and ISO 14001 environmental standards.

When combined with reflective coatings or façade paints, insulation mortars contribute directly to net-zero construction targets.

8 | Common Application Mistakes

-

Over-mixing causes trapped air → lower bonding strength.

-

Applying on wet substrate → leads to delamination.

-

Using low-quality perlite → uneven insulation performance.

-

Skipping primer → reduced adhesion on concrete.

Professional application ensures not just insulation—but the structural reliability of the entire wall system.

The Material Behind Modern Energy Efficiency

A comfortable building isn’t built with thicker walls—it’s built with smarter materials.

YUNYAN’s insulation mortars deliver the perfect balance of lightweight strength, adhesion, and energy retention, empowering builders to meet green standards without compromising quality.

For export partnerships, OEM development, or private labeling, visit YUNYAN’s official website.

For technical datasheets or sample requests, contact our engineering team via contact page and build insulation that lasts for decades.