Description

Oil grouting liquid, namely polyurethane grouting material, is a kind of plugging product, which has the characteristics of no disassembly and rapid plugging. After it is injected into the concrete interior and produces chemical reaction with water, through its slow expansion and continuous pressure, the grouting material can be permeated into the fine gap, expanded and solidified in a short time, to achieve the purpose of complete water stop.

Product Feature

Ø Low viscosity and water contact with a rapid chemical reaction and expansion and solidification

Ø High expansion rate, super-structure elastic colloidal reinforcement, good toughness, low shrinkage characteristics.

Ø The substrate adhesion force is particularly strong and good chemical resistance.

Ø Contact areas with drinking water can also be used.

Ø Suitable for single liquid type high pressure perfusion machine and other machines.

Scope of Application

Ø Dry and wet cracks in filling tunnel, subway, dam, basement, brick material, etc., concrete components, and actual masonry of all contact surfaces.

Ø Crack grouting with hydraulic groundwater flow can be used with low amount of catalyst. Within 2 minutes after contact with water, completely expansion and solidification to form structural elastic colloid.

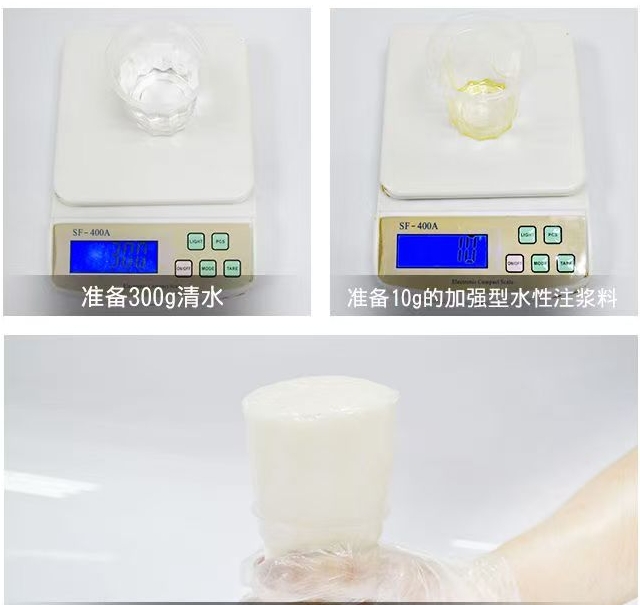

HOW TO USE

Using the power of machinery, the special liquid agent high pressure into the hair crack above 0.02mm, when the agent encountered the crack water will quickly expand to form countless independent closed bubbles will completely block the water outside the structure, in order to achieve waterproof and leakage stop effect. The application of high pressure algae plugging technology is an advanced and effective construction technology all over the world.

PACKAGE: 6KG OR 10KG PER CAN

TECHNICAL DATA

|

Transparency |

Uniform liquid, free of impurities, without layering |

|

Density g/cm³ |

1.28 |

|

Viscosity mPa.s |

360 |

|

Setting time s |

391 |

|

Non volatile content % |

82.9 |

|

Foam rate % |

3243 |

NOTICES:

Ø The temperature during the construction of this product must be higher than 0℃;

Ø When all the leakage points after high pressure grouting to achieve the purpose of complete waterproof leakage, the water stop needle can be removed, and then fill the needle hole with special waterproof mortar to restore its original appearance.

STORAGE:

Ø The products are packaged in a sealed iron bucket;

Ø This product is a non-flammable and explosive material, can be transported according to the general goods, transportation should prevent rain, exposure, freezing, avoid extrusion, collision, keep the packaging intact;

Ø The product must be sealed and stored in a cool and dry place above 5℃; the storage period is 6 months.

YUNYANMIX polyurethane grouting material is manufactured by YUNYAN company, YUNYANMIX is a well branded one of Top 10 for polyurethane grouting material and new building chemicals in China, for a best supplier and wholesaler of new building chemicals please go through: http://www.yunyanchina.com