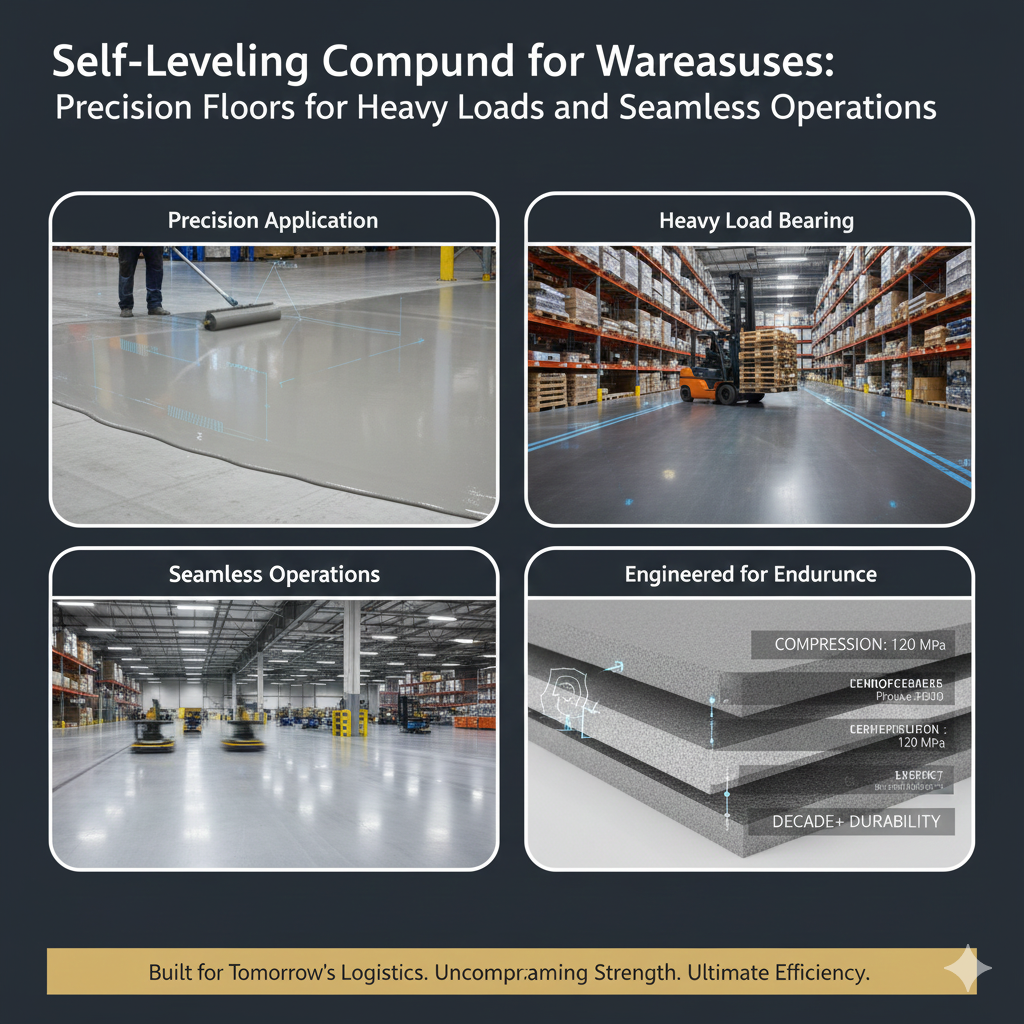

Self-Leveling Compound for Warehouses: Precision Floors for Heavy Loads and Seamless Operations

Every warehouse operates on one silent factor—floor precision.

When pallets roll unevenly, forklifts vibrate, or cracks appear near racks, the problem isn’t logistics efficiency—it’s the ground beneath.

Industrial facilities rely on self-leveling compounds to create surfaces that remain flat, dense, and resilient under tons of mechanical pressure.

In modern supply chains where downtime costs thousands per hour, floor stability is not an option—it’s an operational asset.

1 | Hidden Costs of Uneven Warehouse Floors

Uneven or deteriorating concrete may seem harmless—until operations slow down.

Common warehouse flooring problems include:

-

Forklift vibration, increasing wear on tires and bearings.

-

Poor racking alignment, reducing storage capacity.

-

Water pooling, leading to chemical corrosion and safety risks.

-

Dusting and chipping, contaminating stored goods.

-

Cracks and delamination, caused by heavy or repetitive loads.

A small floor height variation can cause precision equipment deviation up to several millimeters, affecting both automation and safety compliance.

2 | What Makes a Warehouse-Grade Self-Leveling Compound Different

Warehouse environments demand not just smoothness—but strength, load resistance, and durability.

YUNYAN’s industrial-grade compound integrates cementitious binders, high-flow polymers, and micro-fibers to achieve precise leveling with exceptional toughness.

| Component | Function | Technical Impact |

|---|---|---|

| High-Flow Binder System | Ensures perfect leveling | Flatness ≤ 2 mm/2m |

| Reinforced Polymer Network | Improves tensile & adhesion strength | Prevents peeling under forklift traffic |

| Fiber Reinforcement | Reduces microcracking | Maintains surface integrity |

| Shrinkage Compensators | Dimensional stability | Controls curling in large areas |

| Fast Hydration Agents | Early strength gain | Walkable in 4–6 hours |

Performance Index (YUNYAN Warehouse Grade):

-

Compressive Strength ≥ 40 MPa

-

Adhesion Strength ≥ 1.5 MPa

-

Surface Hardness ≥ 7H (Mohs)

-

Curing Time: 24 hours ready for coating

3 | Comparison: Regular Screed vs. Industrial Self-Leveling

| Parameter | Traditional Screed | Self-Leveling Compound |

|---|---|---|

| Application Method | Manual troweling | Pump or pour, automatic leveling |

| Surface Flatness | 5–10 mm deviation | ≤ 2 mm deviation |

| Curing Time | 7–14 days | 24–48 hours |

| Dusting Resistance | Moderate | Excellent (low VOC, sealed surface) |

| Load Bearing | Up to 3000 kg | Up to 8000 kg (with topcoat) |

| Maintenance Cycle | Frequent patching | Minimal maintenance for 10+ years |

Self-leveling compounds outperform traditional screeds in both installation speed and mechanical endurance, making them indispensable for large logistics centers.

4 | Inside YUNYAN’s OEM Manufacturing Workflow

To meet export demands, YUNYAN manufactures OEM self-leveling compounds using precision-controlled production systems:

1️⃣ Automated Material Weighing – ±0.3% accuracy ensures consistent formula.

2️⃣ Uniform Blending – 3D ribbon mixers prevent agglomeration.

3️⃣ Moisture Guard Packaging – Triple-sealed 25kg bags extend shelf life.

4️⃣ Batch Testing – Every lot tested for compressive and adhesion strength (ASTM C1583).

5️⃣ Formulation Customization – Options for fast-dry, high-strength, or epoxy-modified versions.

OEM partners benefit from custom branding, color adjustment, and local market packaging tailored for regional climate and humidity.

5 | Application Process: Fast, Clean, and Consistent

| Step | Procedure | Key Control |

|---|---|---|

| 1. Surface Prep | Clean concrete base, remove oil & dust | Moisture ≤ 4% |

| 2. Priming | Apply compatible epoxy or acrylic primer | Improves bonding |

| 3. Mixing | Add 25–27% clean water | Mechanical mixer for 3 mins |

| 4. Pouring | Spread using rake and spike roller | Maintain wet edge |

| 5. Leveling & Curing | Self-spread under gravity | Walkable within 6 hrs |

The compound naturally levels under its own weight, creating mirror-smooth floors suitable for epoxy, PU, or polished finishes.

6 | Warehouse Application Scenarios

| Facility Type | Challenge | Recommended Formula |

|---|---|---|

| Distribution Centers | High forklift load | High-compressive, fiber-reinforced mortar |

| Cold Storage Warehouses | Thermal contraction | Flexible polymer-modified compound |

| Automated Warehouses | Laser-guided vehicles | Ultra-flat, self-leveling screed |

| Food Storage Facilities | Hygiene requirements | Low-VOC, dust-free system |

| Retrofit Projects | Uneven old concrete | High-bond, quick-dry system |

Each warehouse has distinct demands—but all share one requirement: a floor that performs flawlessly every day.

7 | Common Mistakes and Professional Tips

-

Pouring compound too thick → cracking due to heat buildup.

-

Skipping primer → reduced adhesion and delamination.

-

Poor mixing → air pockets causing surface bubbles.

-

Over-dilution → strength reduction up to 30%.

-

Ignoring ambient humidity → uneven curing or curling.

Pro Tip: Always divide large areas into zones and pour continuously to maintain flow consistency—critical for flatness in large warehouses.

8 | Sustainable and Cost-Efficient Flooring Solution

YUNYAN’s self-leveling compounds are eco-friendly and labor-efficient:

-

Low VOC, non-toxic composition suitable for closed environments.

-

40–50% faster installation than traditional screeds.

-

Up to 60% lower lifecycle maintenance costs.

-

Compatible with solar-powered or automated warehouse systems.

Durability meets sustainability—each bag engineered to extend both floor life and business uptime.

A Floor That Keeps Warehouses Moving

In the world of logistics, the floor is more than a surface—it’s the stage on which the entire system performs.

With YUNYAN’s self-leveling compound, warehouses gain a perfectly flat, wear-resistant, and fast-curing base that supports continuous operations.

For OEM collaboration, technical consultation, or export quotation, visit YUNYAN’s official website or reach our engineering team via contact page.

Let precision flooring drive your warehouse productivity—one perfectly level layer at a time.