Skim Coat Supplier: Achieving Ultra-Smooth Walls for Modern Construction

Every wall tells a story—and it begins with its surface.

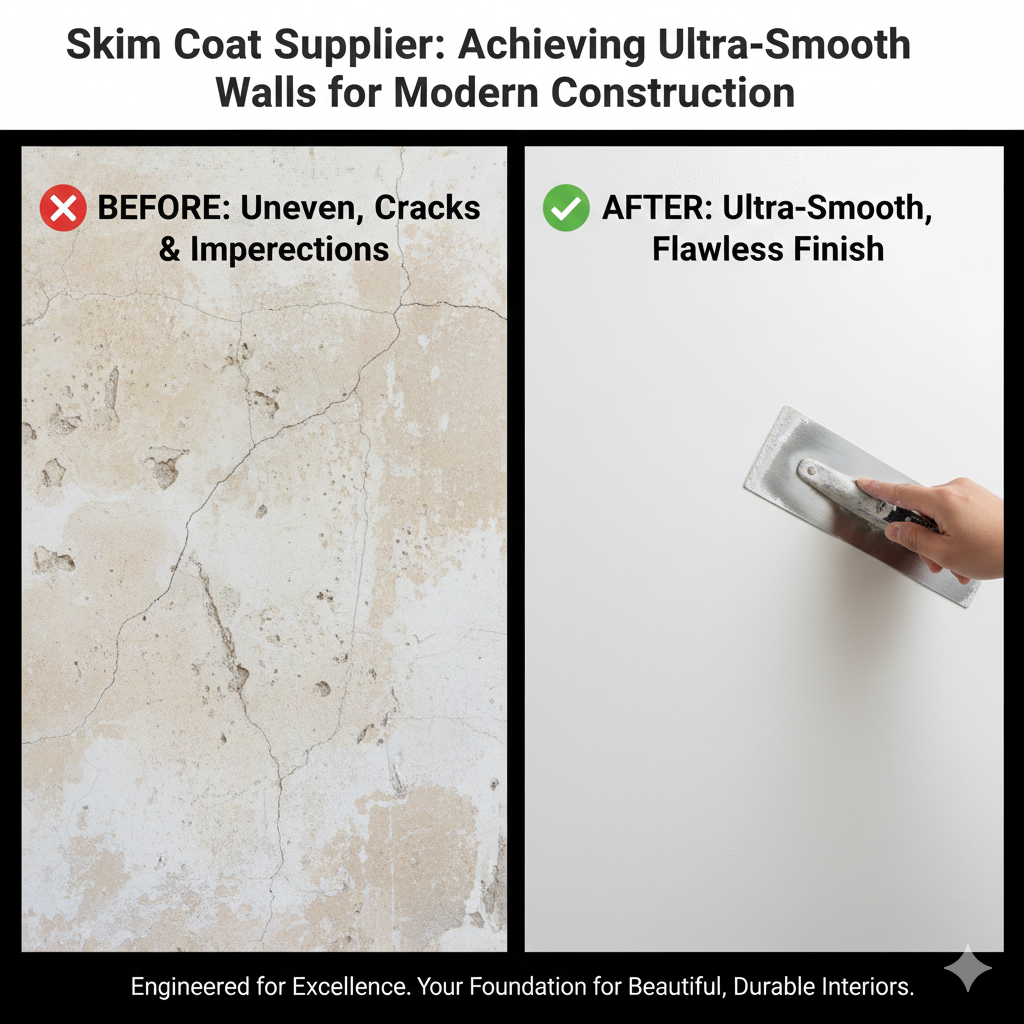

Before color and design come into play, the foundation of quality lies in the skim coat: a thin, even layer that transforms rough concrete or plaster into a flawless, paint-ready finish.

Skim coat is not just a cosmetic layer; it’s the unseen craftsmanship that defines precision, durability, and longevity in modern interiors and façades.

1 | The Hidden Pain Behind Uneven Walls

Even small imperfections on wall surfaces can become major issues later:

-

Paint peeling due to poor surface adhesion.

-

Cracks and crazing from unbalanced curing or substrate movement.

-

Color inconsistency because of differential absorption.

-

Increased paint usage, raising project costs by 15–20%.

In large-scale residential or commercial projects, these flaws can affect brand reputation, inspection results, and maintenance budgets.

That’s why architects and contractors now treat skim coating as an essential precision step, not an optional finish.

2 | What Defines a High-Quality Skim Coat

YUNYAN’s skim coat is engineered with cementitious base, fine mineral fillers, and polymer modifiers—combining strength, flexibility, and a mirror-like finish.

| Component | Function | Performance Advantage |

|---|---|---|

| White Cement Binder | Base strength | Excellent adhesion on concrete, plaster, gypsum |

| Polymer Modifier (RDP) | Flexibility | Prevents cracks and shrinkage |

| Fine Calcium Carbonate Fillers | Texture control | Achieves smooth surface under 0.5 mm |

| Hydrophobic Additives | Moisture control | Reduces water absorption <5% |

| Cellulose Ether | Workability | Improves spreadability and open time |

Technical Data (YUNYAN Standard):

-

Coverage: 1.2–1.5 kg/m² per 1 mm layer

-

Adhesion Strength: ≥0.6 MPa

-

Setting Time: 3–5 hours

-

Whiteness Index: ≥80%

-

Shelf Life: 12 months

3 | Comparison: Traditional Putty vs. Polymer Skim Coat

| Property | Traditional Putty | YUNYAN Polymer Skim Coat |

|---|---|---|

| Adhesion Strength | Low, often <0.3 MPa | ≥0.6 MPa |

| Surface Finish | Coarse or powdery | Smooth & paint-ready |

| Crack Resistance | Poor under temperature changes | Excellent due to polymer modification |

| Water Resistance | Weak | Strong hydrophobic performance |

| Workability | Short open time | Extended, smoother application |

Unlike common filler-based putties, YUNYAN’s skim coat offers a true professional-grade finish—ready for paint or decorative coating without additional sanding or sealing.

4 | Manufacturing Excellence and OEM Capabilities

YUNYAN operates fully automated dry-mix lines equipped with precision batching, moisture control, and export-grade packaging.

Manufacturing Highlights:

-

Computerized formula batching (±0.3% accuracy)

-

Humidity-controlled mixing for consistent particle quality

-

Performance testing per EN 998-1 and ASTM C109

-

OEM customization: adjustable fineness, polymer ratio, and workability for regional climate

Packaging is designed for export durability—25 kg moisture-proof bags with palletized shipping and multilingual labeling.

5 | Application Steps for Professional Results

| Step | Process | Key Control |

|---|---|---|

| 1. Surface Prep | Remove dust, oil, and loose particles | Ensure dry, stable base |

| 2. Mixing | 30–35% clean water | Mix mechanically for 3–5 minutes |

| 3. Application | Apply 1–2 coats with steel trowel | Total thickness ≤2 mm |

| 4. Sanding | Light sanding after full drying | Achieve mirror-smooth texture |

| 5. Painting | Use after 24 hours drying | Compatible with all paint systems |

Properly applied, the skim coat delivers a dense, white, and uniform surface, minimizing paint consumption and maximizing visual appeal.

6 | Applications Across Industry Segments

| Project Type | Application Focus | Recommended Formula |

|---|---|---|

| Residential Apartments | Smooth interior walls | Standard polymer skim coat |

| Commercial Buildings | Consistent color tone | High-adhesion fine finish coat |

| Hotels & Offices | Seamless luxury walls | High-whiteness finishing coat |

| Industrial Facilities | High durability & abrasion | Reinforced skim coat |

| Renovation Projects | Uneven wall repair | Quick-drying flexible formula |

Each variant ensures a stable, long-term base for painting or decorative coatings, enhancing both performance and appearance.

7 | Why Contractors Choose YUNYAN as Their Skim Coat Supplier

-

Certified performance under ASTM C1583 and EN 998-1 standards.

-

OEM-friendly production with flexible branding and packaging.

-

Fast curing & excellent workability for large projects.

-

Moisture resistance & smoothness tested for all climates.

-

Sustainable formulation—low VOC, non-toxic, environmentally safe.

YUNYAN’s solutions are not just materials; they’re systems designed for efficiency, precision, and global reliability.

Perfecting Surfaces, Elevating Finishes

A flawless wall begins long before the paintbrush touches it.

With YUNYAN’s skim coat solutions, builders and designers can ensure every wall is smooth, durable, and visually perfect—meeting modern standards of construction excellence.

For OEM cooperation, project consultation, or regional distribution, visit YUNYAN’s official website or connect directly with our export team via contact page.

Build surfaces that last, with confidence in every layer.