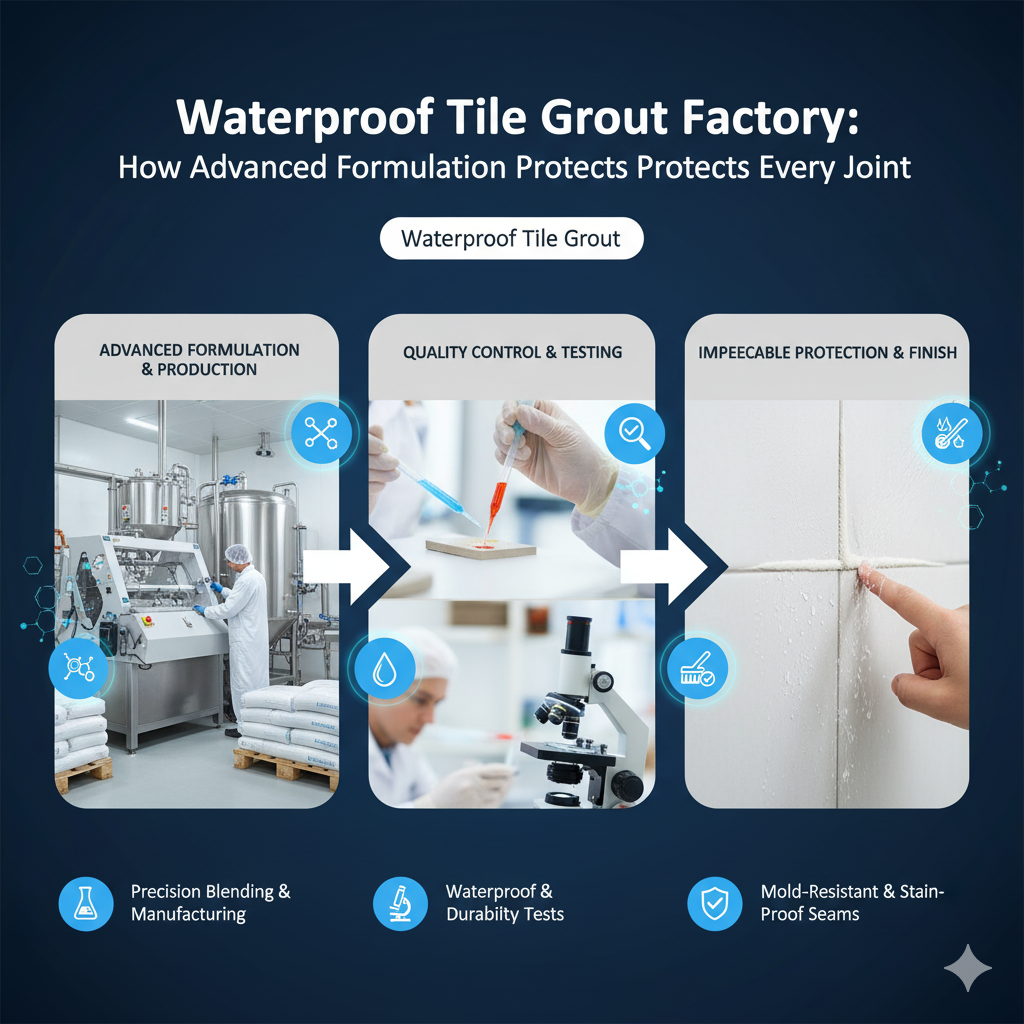

Waterproof Tile Grout Factory: How Advanced Formulation Protects Every Joint

Waterproof tile grout is one of those silent materials that defines whether a beautiful tile installation stays perfect—or starts deteriorating after the first rainy season. When moisture creeps into joints, it doesn’t just stain the surface; it weakens adhesion, feeds mold, and slowly degrades the tile’s foundation.

Factories like YUNYAN have pushed grout design far beyond cement and sand, transforming it into a precise chemical system engineered to repel water, resist bacteria, and extend the life of every tiled surface.

1. The Real Cost of Leaks and Weak Joints

Even minor water infiltration can cause long-term damage. Bathrooms, kitchens, pools, and balconies are exposed to constant humidity and temperature fluctuation. When grout absorbs moisture, it triggers a chain reaction:

-

Efflorescence (white salt deposits) ruining surface color

-

Mold and bacteria growth in damp cavities

-

Tile debonding from substrate swelling

-

Freeze–thaw cracking on outdoor facades

Traditional grout, no matter how well mixed, remains porous. Water doesn’t just stay on the surface—it seeps through, reacts with cement hydrates, and shortens the installation’s lifespan.

2. How Waterproof Tile Grout Works

Waterproof performance isn’t achieved by sealing the surface alone; it begins inside the formulation.

A waterproof tile grout factory designs its recipe with polymers and fillers that form hydrophobic networks once cured.

Core Functional Components

| Component | Function | Result |

|---|---|---|

| Redispersible Polymer Powder | Creates water-repelling film | Blocks capillary absorption |

| Silane Additives | Improves bonding and hydrophobicity | Prevents microleakage |

| Fine Quartz & Silica | Densifies matrix | Enhances strength |

| Anti-Fungal Agents | Prevents mold growth | Keeps joints hygienic |

| Pigment Stabilizers | UV resistance | Color durability outdoors |

These ingredients transform grout from a water-absorbing filler into a barrier material.

Unlike surface sealants, this protection exists throughout the entire joint depth.

3. What Happens Inside a Professional Grout Factory

A genuine waterproof tile grout factory functions more like a materials laboratory than a traditional cement mixer. The production process is systematic and precise:

-

Raw Material Selection: Verified cement grades, polymers, and aggregates screened for purity and grain size.

-

Automated Mixing: Computer-controlled blending ensures consistent ratios batch to batch.

-

Moisture Testing: Samples tested under 24-hour immersion and vacuum conditions.

-

Curing Simulation: Accelerated aging tests for shrinkage and color stability.

-

Packaging & Traceability: Every batch coded for QC tracking and export documentation.

By integrating chemical engineering into production, factories like YUNYAN maintain uniform quality for both domestic and overseas markets—critical for large-scale projects that rely on predictable performance.

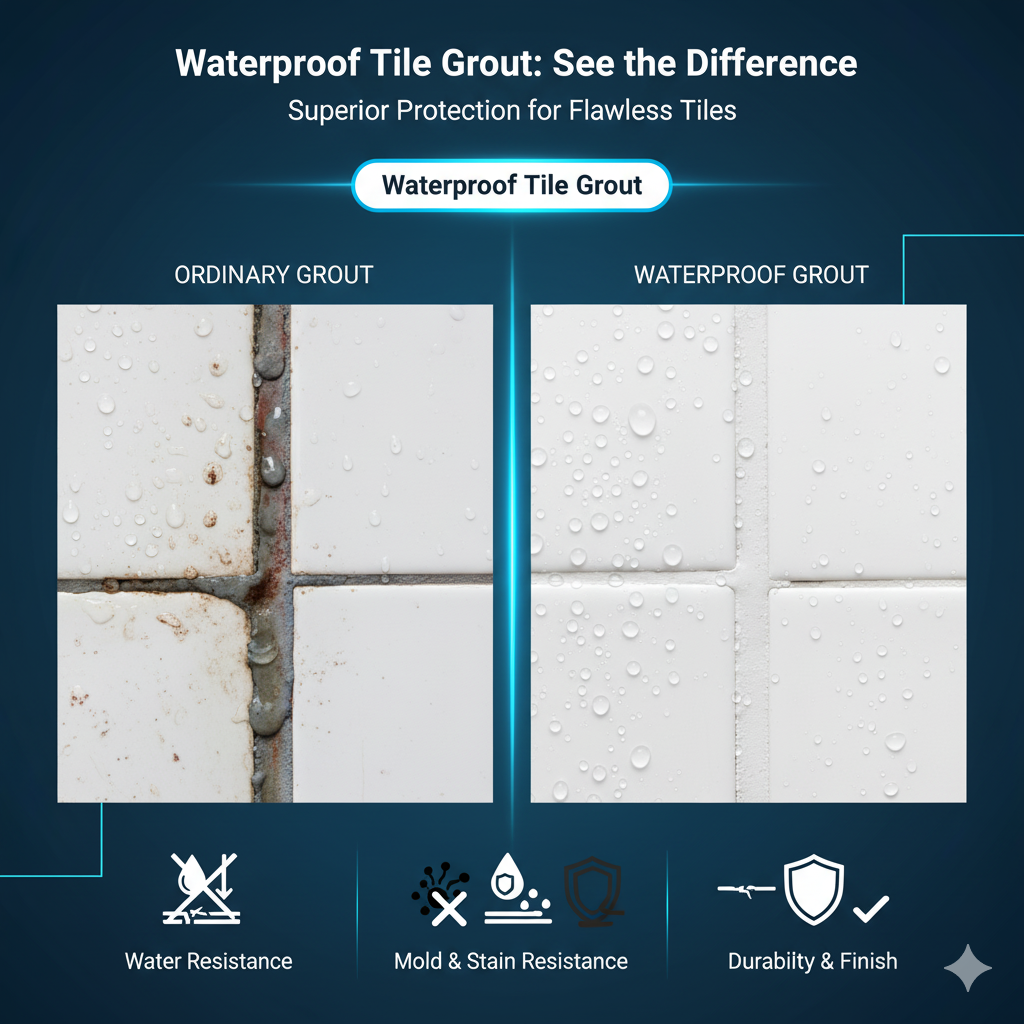

4. Comparing Waterproof and Standard Grouts

| Property | Standard Cement Grout | Waterproof Tile Grout |

|---|---|---|

| Water Absorption | 4–6% | < 0.5% |

| Mold Resistance | Moderate | Excellent |

| Bond Strength | Medium | High |

| Shrinkage | Moderate | Controlled |

| UV Resistance | Low | Improved |

| Cleaning Maintenance | Frequent | Easy wipe |

| Longevity | 3–5 years | 8–10 years |

The difference lies not only in chemistry but also in factory control—consistent moisture content and precise additive ratios ensure that waterproof grout performs identically across thousands of bags.

5. Where Waterproof Tile Grout Excels

Bathrooms and Kitchens

Constant humidity makes these spaces prone to discoloration and mold. Waterproof grout ensures clean joints and longer service life.

Swimming Pools and Water Features

Continuous water exposure requires non-absorbent grout. It resists chemical damage from chlorine and prevents cracking during thermal cycling.

Exterior Walls and Facades

Weatherproof grout prevents water ingress behind tiles, protecting the structural envelope of buildings.

Balconies and Terraces

Outdoor joints face rain, heat, and movement—only hydrophobic, flexible grout can handle the expansion stress without leaks.

6. Selecting the Right Grout Formula

Choosing grout should depend on the site’s environment and maintenance expectations.

Selection Guidelines:

-

Indoor dry areas: Standard polymer grout

-

Bathrooms & kitchens: Waterproof polymer-modified grout

-

Pools & outdoor walls: High-density, UV-resistant waterproof grout

-

Renovations: Low-shrinkage, fine-grain grout compatible with existing tiles

A factory’s technical data sheet (TDS) is the best reference—it reveals real test data like water absorption rate, compressive strength, and color stability rather than marketing terms.

7. Why Factory Production Matters

Small-scale mixing cannot replicate the stability achieved by industrial-grade batching.

Inconsistent ratios cause uneven curing, color variation, and reduced water resistance.

Factory production guarantees repeatable chemistry, which is vital for large projects such as hotels, pools, or residential complexes.

Moreover, modern facilities utilize closed-loop dust control, automated bagging, and moisture-regulated silos—ensuring not only product quality but also environmental safety and export compliance.

The Invisible Barrier That Keeps Tiles Beautiful

A truly waterproof tile grout is more than a material—it’s an engineered defense layer built within every joint.

When designed and produced under strict quality control, it prevents leaks, discoloration, and bacterial damage long after installation.

For architects, contractors, and distributors seeking long-lasting water-resistant grout systems, more technical details are available on YUNYAN’s official website.

For inquiries, bulk orders, or formulation customization, contact the factory directly through the contact page—and ensure every project stays sealed, strong, and spotless for years.